Product Features:

◆ Dual Color led strip at 12V 24V.

◆ Main chips quantity per meter is 576pcs.

◆ CRI have 90+

◆ The PCB width is 10mm.

◆ The backing 3M can be another type as you want. Normal use is yellow 3M.

◆ Waterproof IP: IP20

◆ Color is: 2700K – 6500K

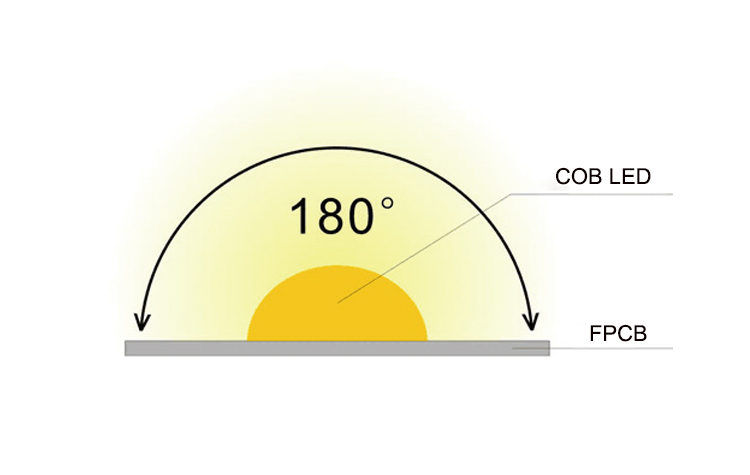

◆ Beam :180°

COB led strip specification

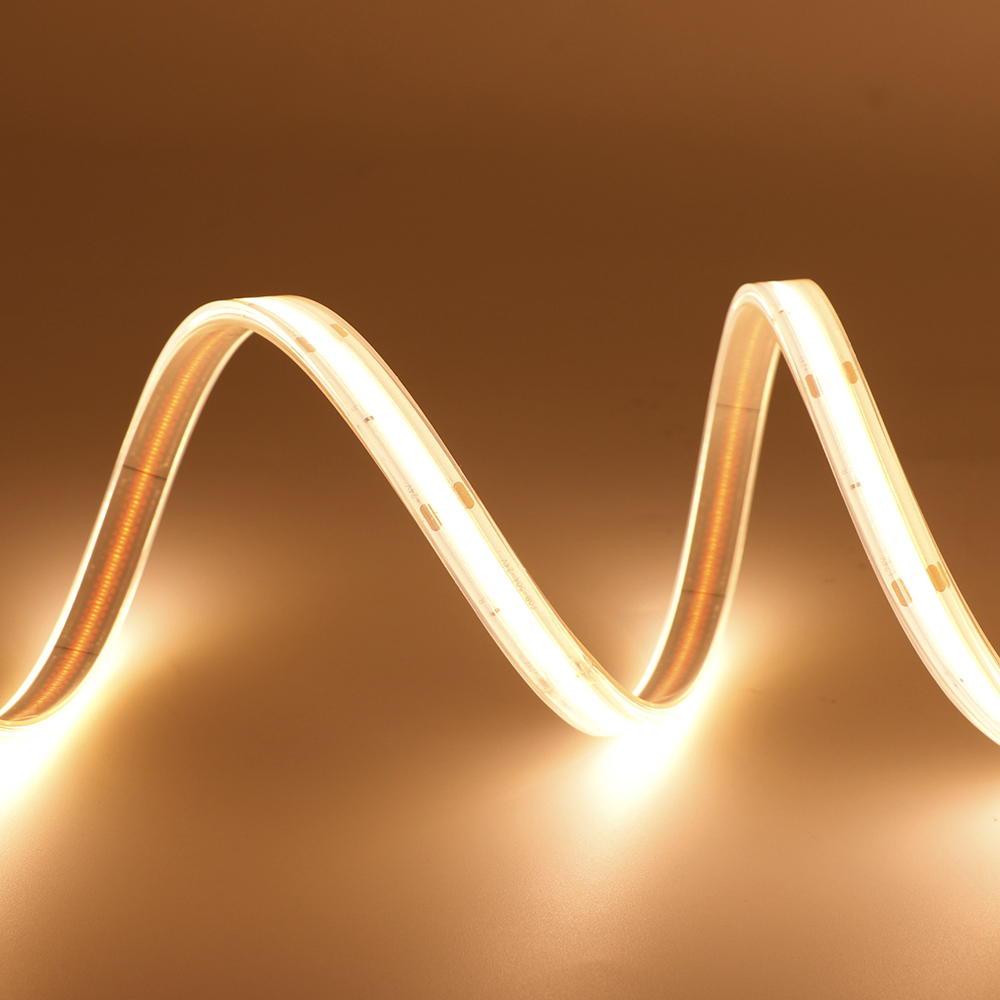

The COB led strip is a very good used for cover, Cabinet & Furniture soffit lighting, showcase and display path and contour making. Edge, and back lighting.

| Part NO: | LW-COB125 | 2700K | 6500K |

| LED Qty: | 576pcs per meter | 288pcs per meter | 288pcs per meter |

| CRI (RA) | 90 | 90 | 90 |

| Input Voltage: | DC12V/DC24V | DC12V/DC24V | DC12V/DC24V |

| Watts: | Single Color 8W Mix Color 16W |

8W | 8W |

| IC QTY: |

12V(18 pcs IC) 24V(12 pcs IC) |

12V(18 pcs IC) 24V(12 pcs IC) |

12V(18 pcs IC) 24V(12 pcs IC) |

| Color: |

Addressable Dual Color White 2700-6500K |

2700K | 6500K |

| PCB Color: | White | White | White |

| IP Grade: | IP20 | IP20 | IP20 |

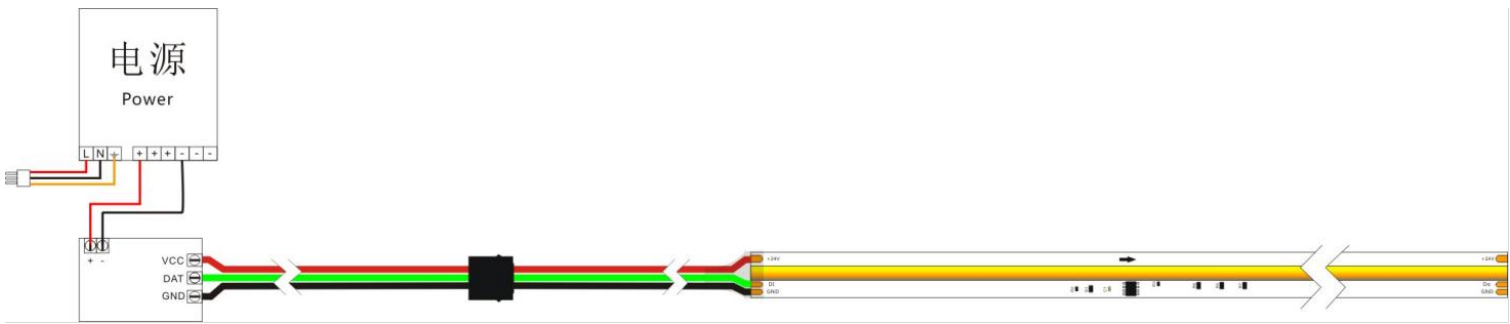

| Control Signal: | SPI | SPI | SPI |

| Beam angle: | 180 degree | 180 degree | 180 degree |

| Certification: | CE; RoHS | CE; RoHS | CE; RoHS |

| Max Run: | 5M | 5M | 5M |

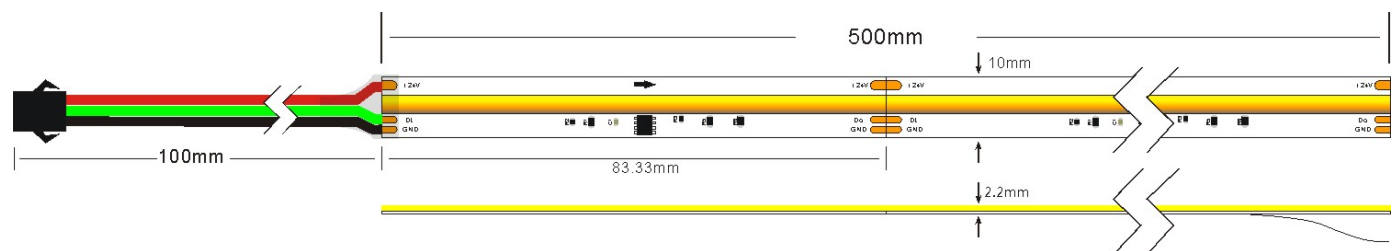

| Min Run: | 12V(55.55mm) 24V(83.33mm) |

12V(55.55mm) 24V(83.33mm) |

12V(55.55mm) 24V(83.33mm) |

| Dimension IP20: | 5000 x 10 x 2.2mm | 5000 x 10 x 2.2mm | 5000 x 10 x 2.2mm |

| Dimension IP67: | 5000 x 12 x 4.9mm | 5000 x 12 x 4.9mm | 5000 x 12 x 4.9mm |

Products Details:

1. Wide viewing Angle up to 180 degree.

COB led strip are 180 degree viewing angle. SMD LED Strip type is normally 120 degree viewing angle.

Put the chips on board then put Phosphor on chips let the viewing angle bigger, then it’s less dark zone

2. Excellent CCT uniformity for continuous orders.

With our experience engineer team. we can keep excellent CCT uniformity for continuous orders. and keep Color- Consistency: 3 SDCM.

Ensure your every orders same color, and continuouse provide super work for your customers.

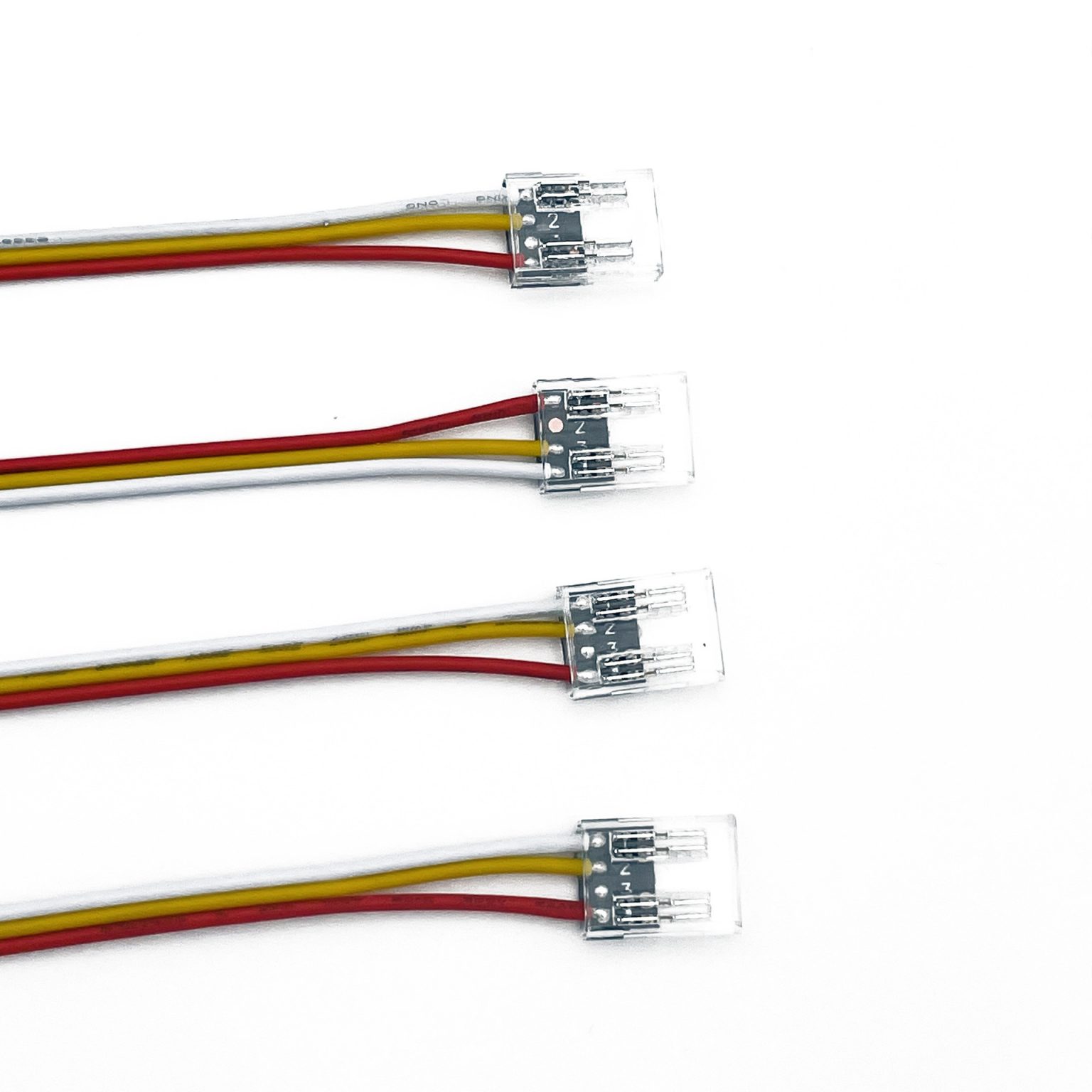

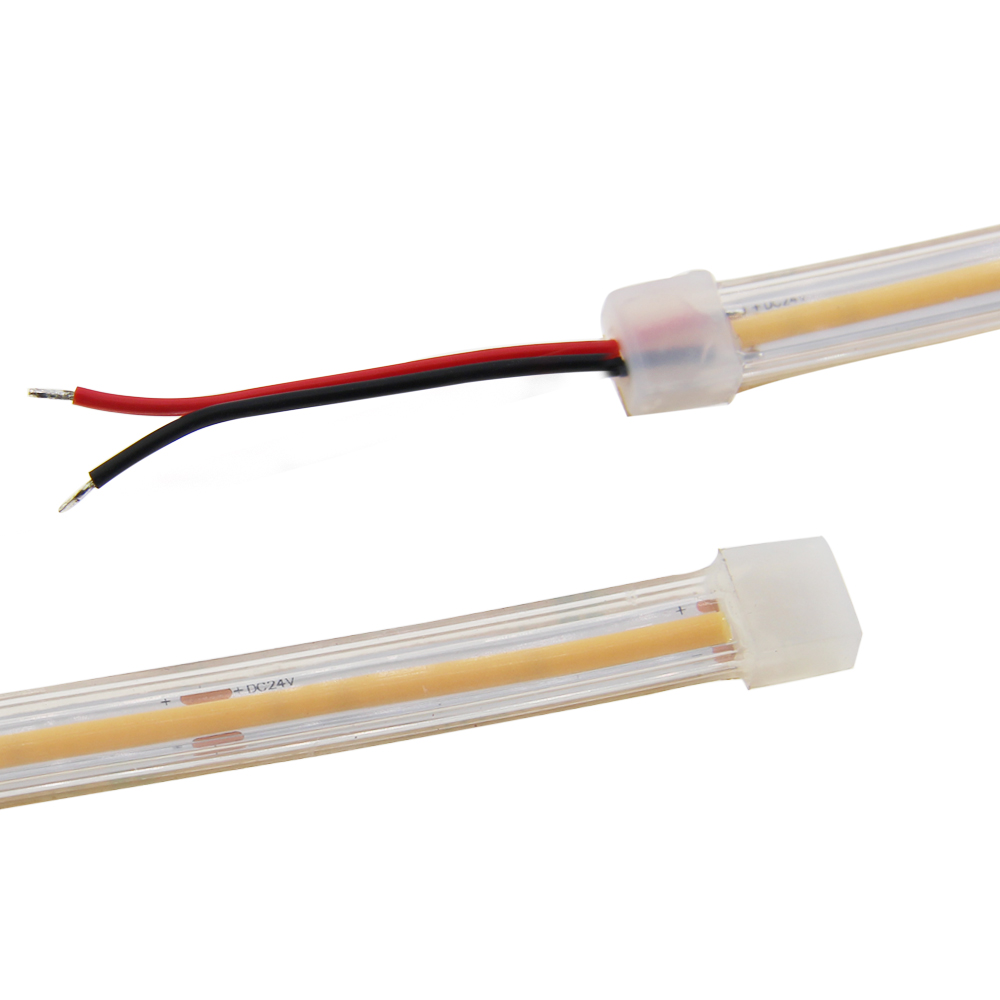

3. 22AWG PURE COPPER WIRE

We pay attention to every details, the connect cable we use 22AWG pure copper wire. Always keep 3/8”stripped off the end of the LED for wiring purposes.

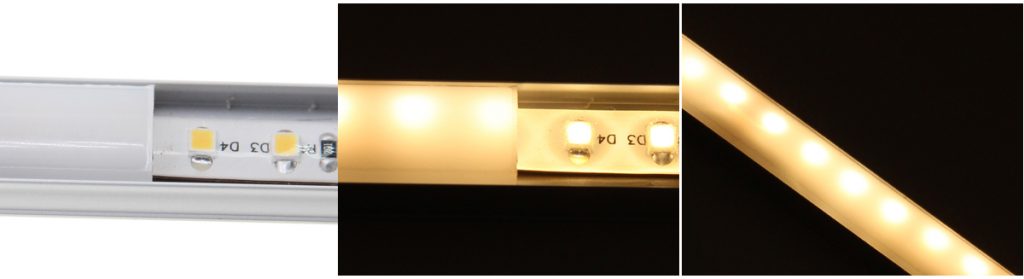

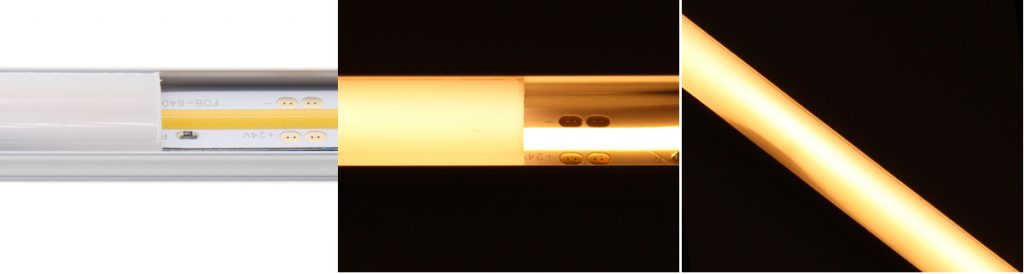

4. Excellent Iinear Iighting performance, Dot FREE.

2835SMD Led Strip With Aluminum Profile:

VS

COB SMD Led Strip With Aluminum Profile:

5. Waterproof type.

Non waterproof type

Extruded Silicone waterproof

Put in tube waterproof

6. Very nice color and it’s main color temperature.

Dual Color LED Strip Lights

2700K COB LED Strip Lights

6500K COB LED Strip Lights

7. High CRI type, based on 90, even RA > 95

8. Dimensions:

24V-LW-COB125

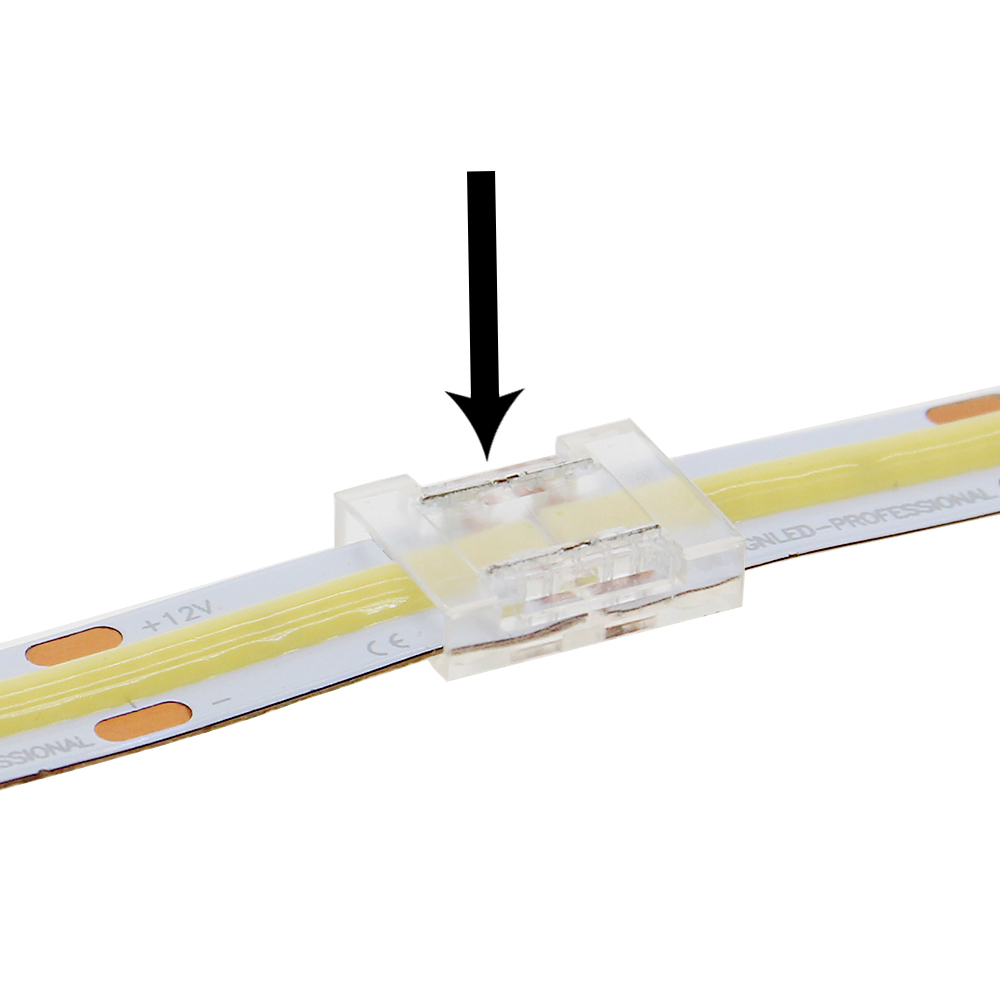

9. Connect drawing:

How to cut and connect it

1. Cut the COB on the cut mark.

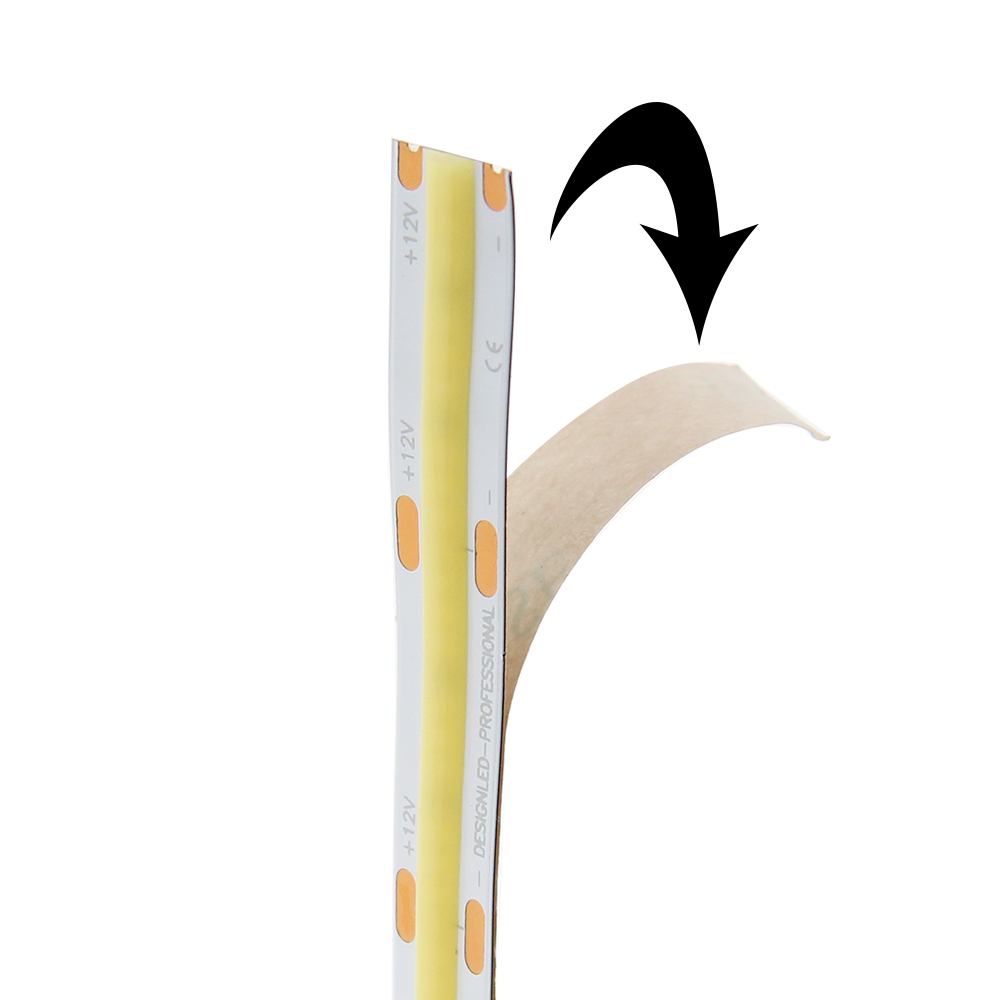

2. Take the 3M tape out.

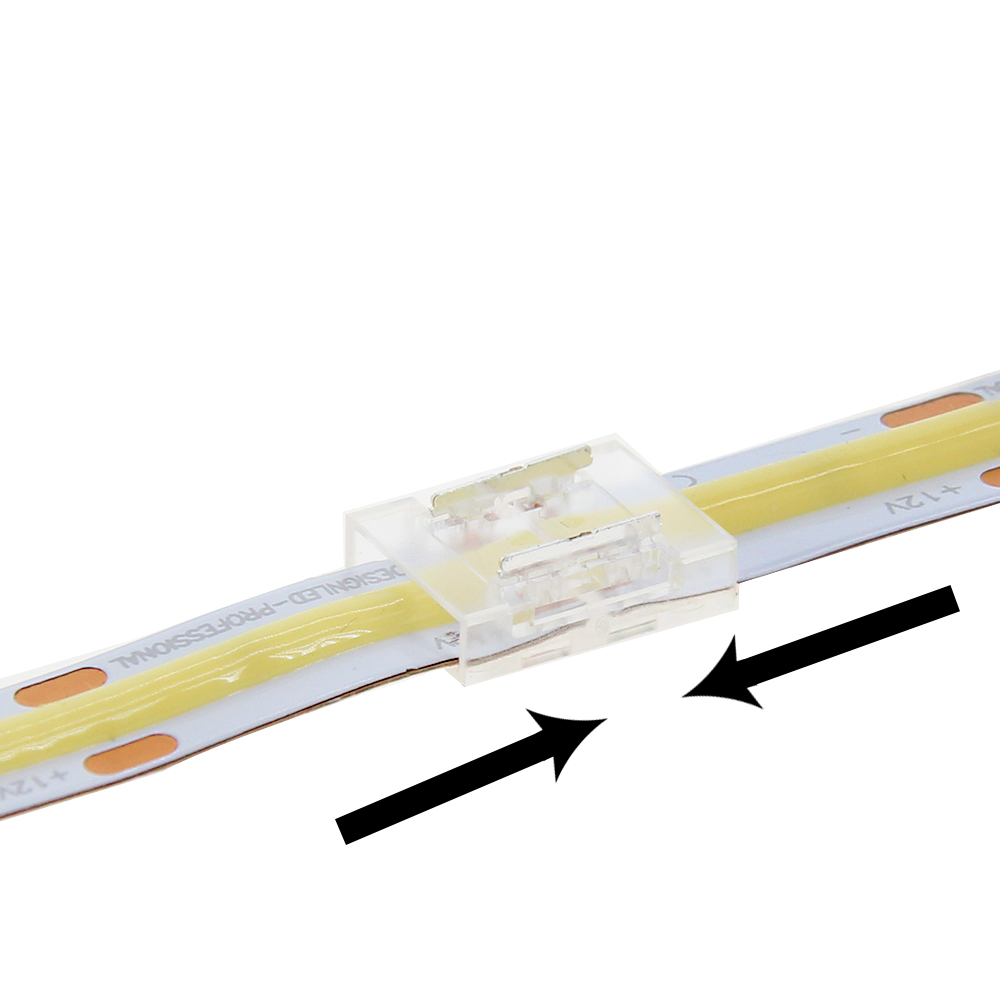

3. Put the strip with the connector and connect it together.

Application:

Packing:

Box Size: 43*43*35cm 100 reels per box

Weight: IP20: 12KG

5 of the Most Common Customer Questions (FAQ)

Two-color COB LED STRIP refers to the dimming of COB LED STRIP through a dimming controller, which can obtain any color temperature from 2700K to 6500K.

Yes, COB LED STRIP can be cut.

Yes, it’s can be dimmable with dimmer controller.

- The light-emitting chip adopts flip-chip technology, which has a cost advantage with the same number of lamp beads.

- Shorter heat dissipation path and lower thermal resistance, less light decay.

- No silver plating, no vulcanization risk

- Lighting angle can reach 180 degrees

- Poor color consistency control.

This is determined by the difference in the manufacturing process of COB LED STRIP and SMD light strips. The production process of SMD led strip is to first produce SMD lamp beads, and then split each lamp bead, and make the light bead after light separation to achieve color consistency on the same board. The COB LED STRIP is to flip the chip on the PCB board, and then drop the phosphor to achieve white light. Without the steps of light splitting, there is no way to achieve the consistency of the SMD led strip.

- Low power

Because the chips of the COB LED STRIP are too dense, it will affect the heat dissipation, so the power cannot be made too large, at most 14W per meter, and the SMD lamp beads of the SMD led strip have brackets, which can dissipate heat and can achieve 18W.

- Low luminous efficiency.

At present, the highest luminous efficiency of COB LED STRIP is: 120LM/W. SMD has a high-power lamp bead that can achieve 160-170LM/W. If the power requirement exceeds 120LM, you still need to choose a high-brightness SMD led strip.

- Flip chip, the defect rate is higher than that of SMD led stripwhen making waterproof led strip.