Neon LED Strip Manufacturer

Contents

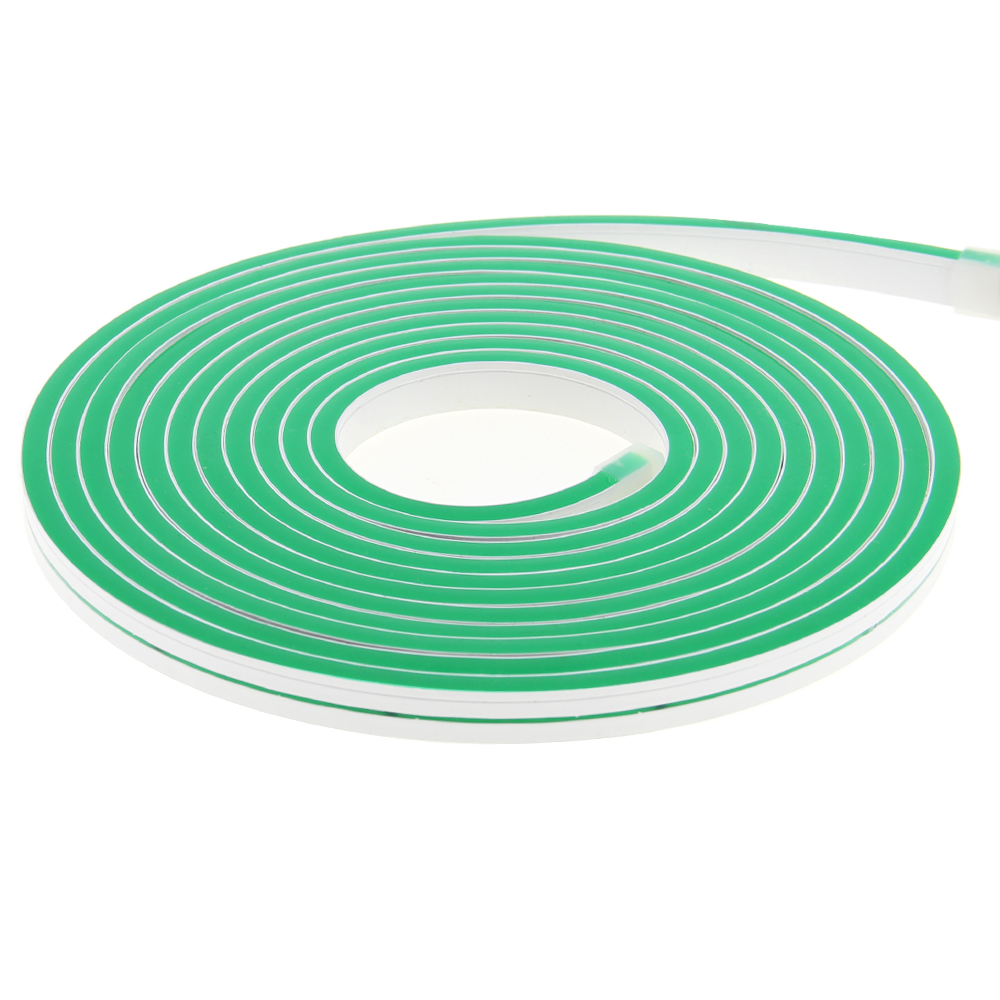

1 , Flexible LED Neon Light Strip:

2 , LED Neon Light Applications:

3 , Division of LED Neon Strips:

3.1 , According to the manufacturing method:

3.3 , By the Amount of Molding:

4 , Accessories for our Flexible LED Neon Light Strips:

1 , FLEXIBLE LED NEON LIGHT STRIPS:

The effective lighting design of Neon strip lights has been in use since its invention in 1910 at the Paris Motor Show. The original construction of the lights was rudimentary but powerful. The neon lights worked by getting a glowing discharge of colored light created by sending voltage through electrodes in sealed glass tubes containing rarified gas. While this design was not the most durable, it did revolutionize the lighting world. Businesses from all over wanted to illuminate their buildings with as much neon light as possible. Cities like New York, Chicago, Los Angeles, St. Louis, and of course, Las Vegas purchased all the neon lights they could get to bring in more customers.

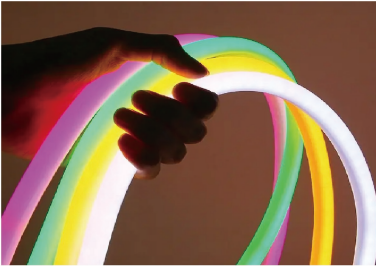

Today, neon signage is experiencing a significant comeback. The high electric cost, environmental concerns, and possible health effects of the old design forced the technology to change into safe, durable, and wonderfully brilliant flexible LED neon light strips. The breakthrough technology of LED, or light-emitting diodes, uses neither glass nor neon gas. They are made from acrylic thermoplastic, which is lightweight, shatter-resistant, and highly effective at transmitting brilliant light.

Now businesses, theaters, entertainment venues, and even private homes can experience the nostalgia of beautiful neon lights in the more efficient LED form factor. Light up your storefront and bring the beauty of neon to your business by contacting us today!

The LED Neon strip have below advantages:

2,LED Neon Light Applications:

Flexible LED neon lights are becoming the gold standard in light tech design all over the United States. You can see them being utilized in outdoor venues like museums, hotels, gyms, schools, concert halls, clubs, bars, and hotels.

They also make excellent indoor lighting choices like shopping mall advertising, backlighting, aisle lighting, decorations, and even playgrounds. The recent popularity on social media sites has increased the demand for flexible LED neon lights in people’s apartment buildings, dorm rooms, and private homes. They make a great outdoor lighting improvement to your backyard area.

The flexibility of the LED neon strips allows you to vary your design from occasion to occasion. You should know some information before installing so you can choose the best product for your lighting design needs.

After installing the flexible LED neon light strip outdoors, the problems that should be paid attention to.

The waterproof treatment done at our manufacturing center is different depending on the type of molding performed. The one-time forming adds waterproof connectors and a stainless steel round hoop reinforced plug at the line opening to strengthen the waterproof performance. The double forming is bought, then cased according to your customized order. Special attention will be paid to the waterproofing at the interface location during processing. There is more information available about waterproofing below.

Aging is an unavoidable problem with any style or design of lighting strips. Poor quality strips are made with bad gels that can get yellow and brittle in outdoor conditions. This may lead to fractures, short-circuits, and water-caused damage. We pride ourselves on using high-quality products but still suggest that the buyer keep an eye out for aging as a precautionary measure.

Please any thermal expansion/contraction due to inclement weather ,note that countries like Canada, the USA, UK, and Russia should be cautious when the outdoor temperature falls below freezing. In those cases, you may want to move your display indoors so the controller works correctly. The same is true for countries with extreme heat, like Mexico, India, and Iran.

When you install the flexible LED neon light strips in bars, shopping malls, and concert venues, take note of your power supply. While the LED technology does not require a significant power source, it is better to have them plugged into a reliable supply to avoid aging problems.

3, Division of LED Neon Strips:

3.1,According to the manufacturing method:

(1)Placing the LED Neon Strips into Sleeves

The first part of our production process is to place your LED strips into two-extruded tricolor molding sleeves. These durable sleeves allow for a higher light transmittance by controlling any unwanted light loss for brighter color performance. The reinforced

design of the sleeves effectively protects the LED light board inside from displacing. This way, you will not have to worry about any back and forth rubbing inside the strips that might damage the product. This is especially important during installation or for use cases involving a lot of transportation, setup, and breakdown. Our sleeves allow for bending and twisting without damage to the light board inside. We can customize your order for any length, color scheme, or voltage because of the flexibility of the sleeves. With only a dozen or so strips, hundreds of neon strips can be made, significantly reducing our need for inventory so we can pass along those savings to our customers.

(2)How our Neon Strips are Extruded

Here is a quality video that shows part of our manufacturing process. We have two different methods of manufacturing our neon strips. The first is by making the neon tube separately and then inserting them directly into our durable sleeves. The second method is when the LED strip and neon tubes are placed together into our machines and extruded during the production phase fully formed. To get a better understanding of how our LED neon strips are made, please watch the manufacturing process in the video below. We maintain a clean and safe work environment where you can see our strips hanging at different lengths to prepare for custom orders worldwide.

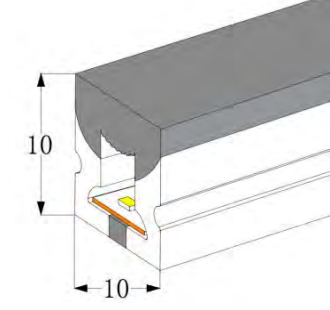

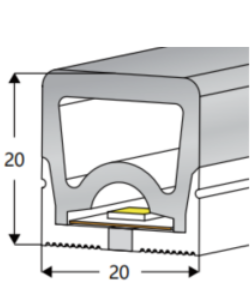

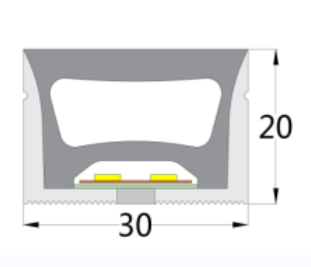

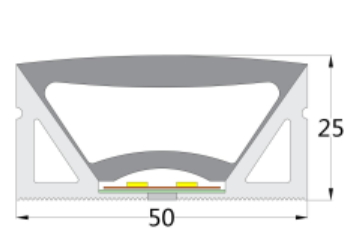

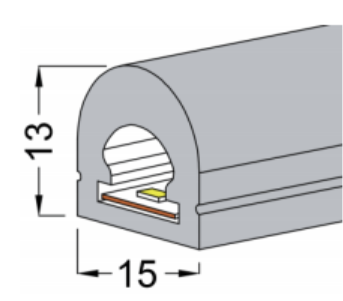

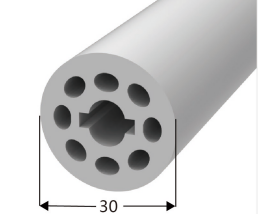

3.2, By Size:

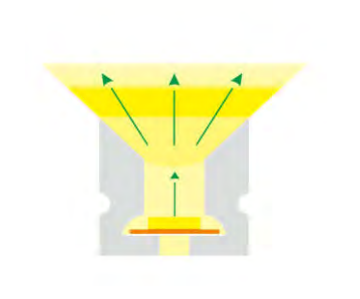

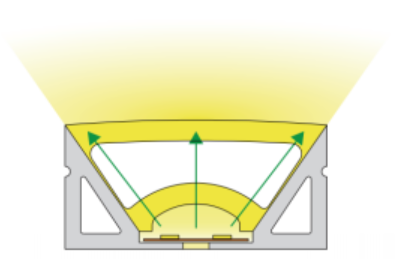

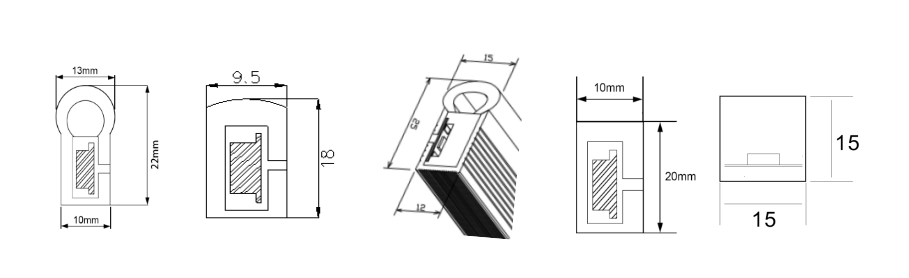

The common flexible LED neon light strip sizes available are 6 X 12mm (0.24” X 0.47”), 7 X 14mm (0.28” X 0.55”), 15 X 15mm (0.59” X 0.59”), 10 X 22mm (0.39” X 0.87”), and 10 X 18mm (0.39” X 0.71”). These sizes come in either the traditional square design or mushroom head style. The square-shaped design has a larger luminous angle. The mushroom head shape design utilizes a light filtering effect which reduces light spots.

3.3, By the Amount of Molding:

Our flexible LED neon light strips are available in two different types of molding. The first is when we only do one round of forming by putting the glue and strips through our finely tuned machines. The result is a standard light strip with all the benefits of the LED technology, typically with a white adhesive color for the base and transparent light area.

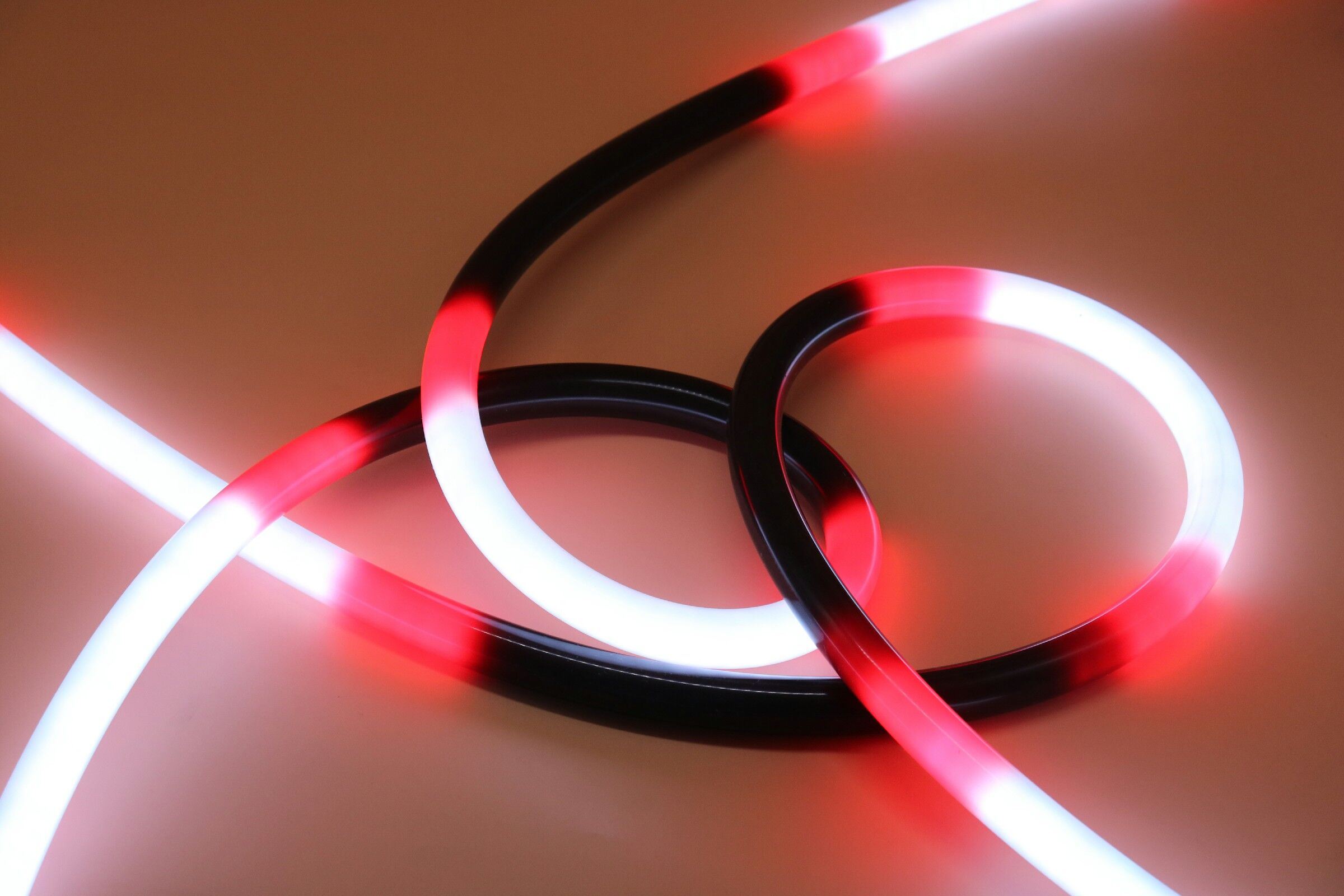

Our second molding style is what most light designers prefer. In this molding, we place our strips through our machines for a second time but include a different color adhesive that you select in your order. This double forming creates unique light designs by allowing the base and glowing surface to be colored per your individual requirements. When the LED neon strip base is white, the surface is transparent, focusing the light on the luminous surface to avoid light leakage. When the base is black, the luminous surface will appear brighter. When the glowing surface needs to red or green, our molding process allows for higher blending into background walls or set designs. There is also the possibility of making the whole light body black. This creates a non-luminous black tube for easy hiding in your lighting design while still providing an incredibly stunning glow when the lights are turned on.

Two times molding:

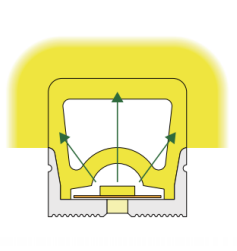

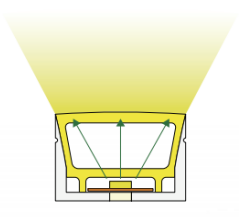

3.4, By the Emitting Side:

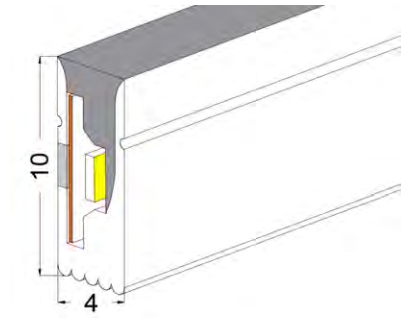

We offer both front-emitting and side-emitting styles of flexible LED neon light strips. The different designs offer you more customization over what kind of outward light display you desire. The following pictures show our front-emitting 10 X 10mm design and our side-emitting 10 X 4mm design.

Front-Emitting

Side emitting

Semicircle

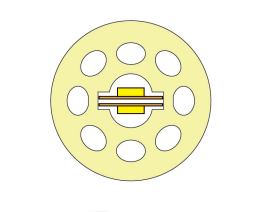

Round

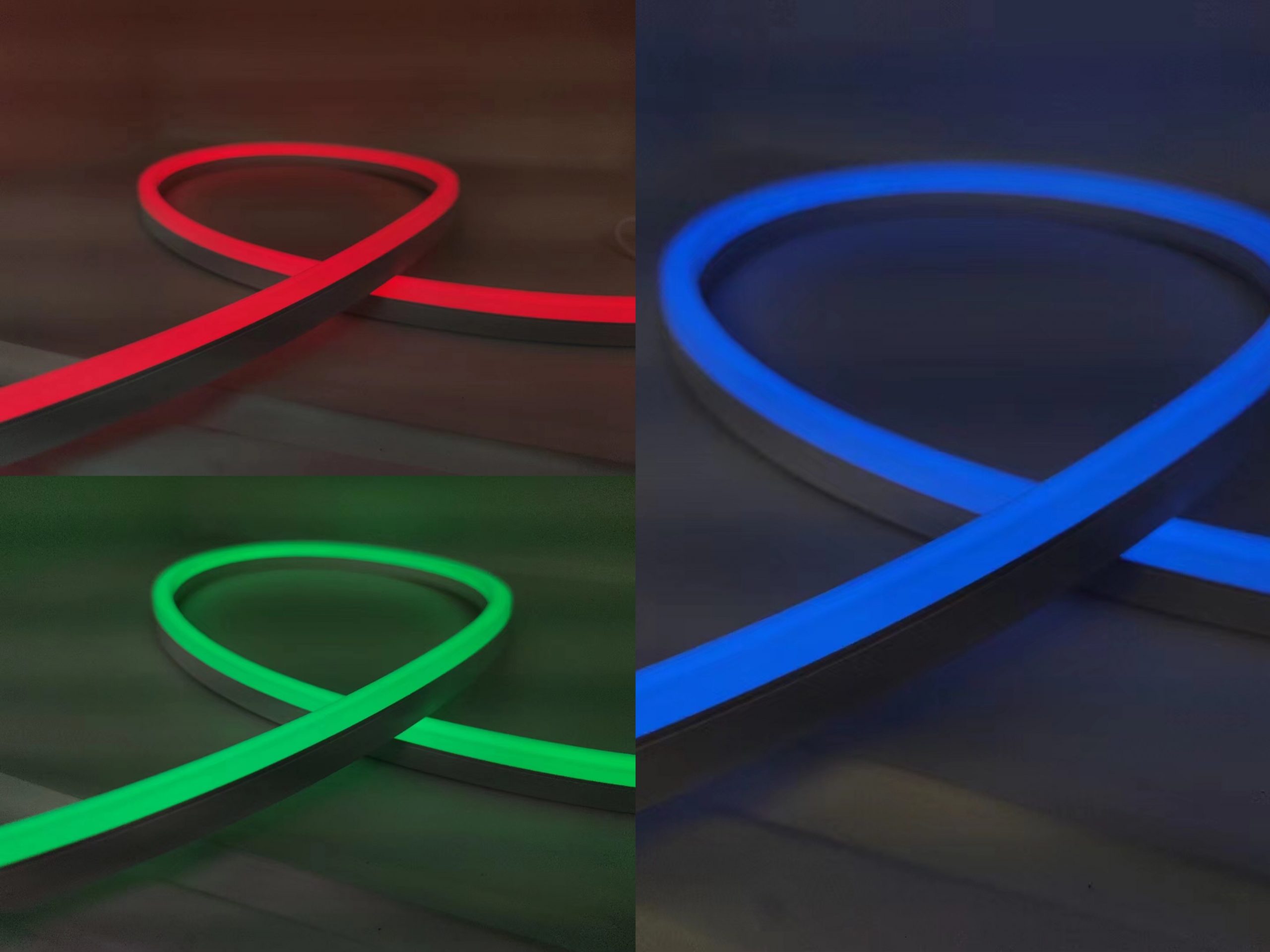

3.5, By the Emitting Color:

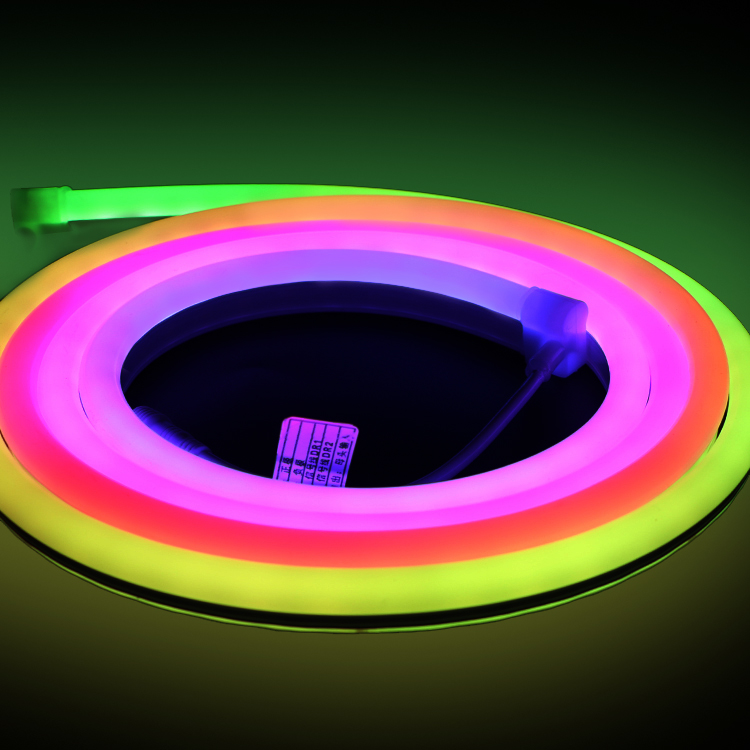

Our flexible LED neon light strips are available in a single color, full RGB spectrum, and addressable styles. Addressable neon strips are unique because they are made with the IC all-electronic neon transmitter. This makes it possible for that style of the strip to have several different colors appear on the same length simultaneously.

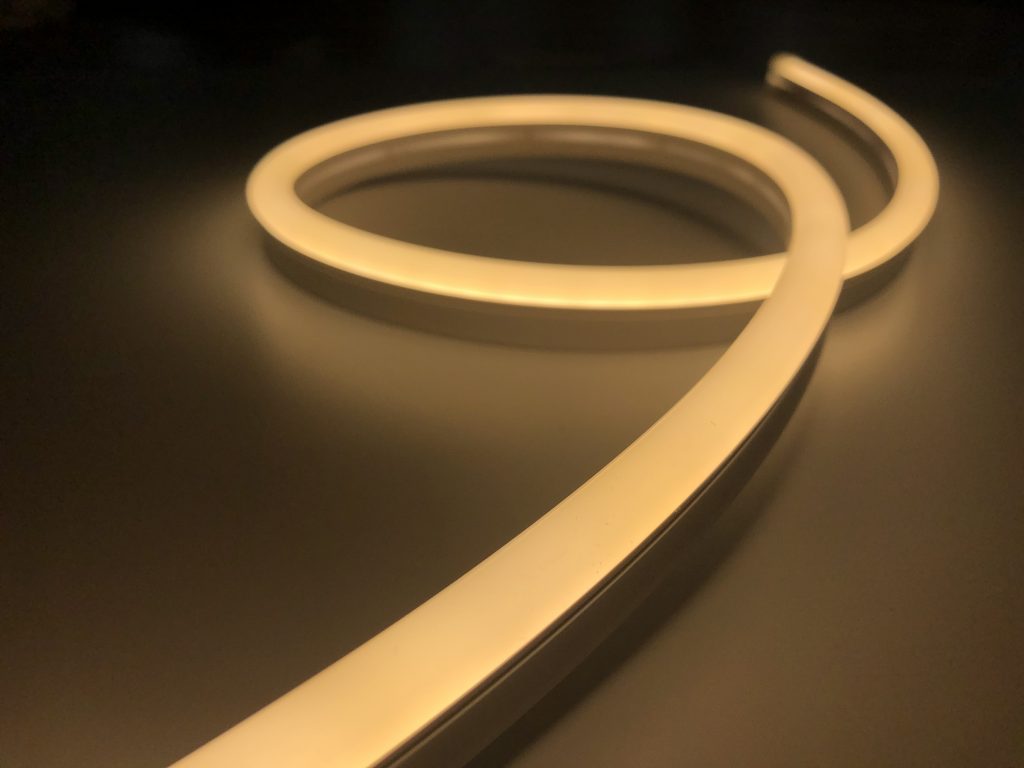

Single color Neon LED Strip:

RGB,Addressable RGB Neon LED Strip:

4,Accessories for our Flexible LED Neon Light Strips:

(1),Controller

One of the best features of our flexible LED neon light strips is our variety of controllers. These controllers give you numerous capabilities for your lighting design, including dimming, fading, jumping, spinning, Madrix, Bluetooth, and APP control.

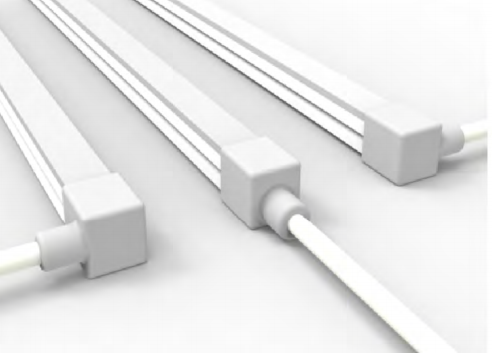

(2),End Caps

Our molding fits easily into end caps to make your installation, breakdown, and setup processes a lot faster. The end caps come in different styles, including right end cap, left end cap, straight end cap, tail end cap, and mounting clips.

Clips (aluminum clips) the different sizes of flexible LED neon light strips have different sizes of clips.

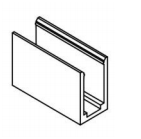

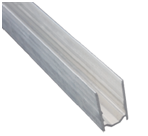

(3),Aluminum Profile

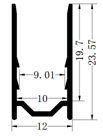

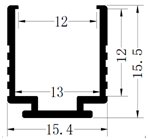

The sleek aluminum profile of our flexible LED neon light strips is used to hold the actual strip in place on your mounting surface. This varies depending on the overall size of the strip you order and the style of the glowing surface.

(4),Waterproof Connectors

When your next lighting design includes water features, or outdoor displays, take advantage of our waterproof connectors. They are available in different sizes to ensure your flexible LED neon light strip is protected.

5,INSTALLATION OF NEON STRIPS:

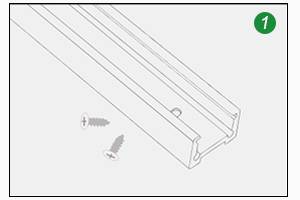

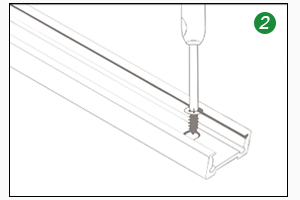

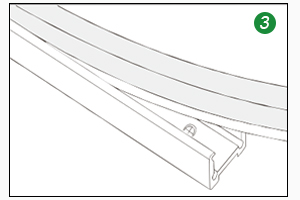

We offer two different methods of installing your flexible LED neon light strips. The first is for using the aluminum profile. You start by fixing the aluminum slot into the desired position. Then you put the screws into your spaces and gently place the light bar inside. This ensures a suitable straight line for your light design.

Accessories

(Clips+Screw+Screwd-Diver)

Fix the Aluminum Tank

Put in the Linear Light

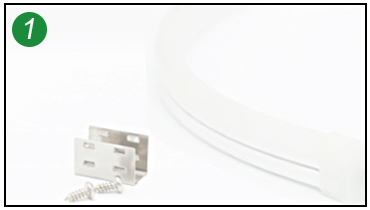

The second type of installation uses our clips. This allows for more pliable shape building. Start by fastening the clips with screws into your desired position. Then you gently place the light bar inside and watch the display come to life.

Accesssories(Clips+Screw+Screwd-Diver)

Fixed Clips

Install the Linear Light

Fixed the Linear Light

6,Product Market Conditions:

PVC and silicone neon strips are primarily used in the current market. PVC has a lower cost for production but is not as resistant to yellowing or aging as we would like. Silicone is more resistant to yellowing and comes in at a slightly higher cost. Our LED neon strips have:

- Professionally designed structure with even soft light, dot-free, and excellent color temperature consistency.

- Resistance to yellowing, aging, high and low temperatures and can be used in harsh outdoor and indoor environments.

- Corrosion-resistance, resistant to weak acids and alkaline salts.

- Proven waterproof performance with a waterproof grade IP67 standard.

- Good flexibility, resistance to folding and pulling, and easy to shape for convenient delivery.

- Added fold and tensile strength resistance with our base plates.

- Ability to be cut to any customized length for your needs.,

Compare Neon led strip with all kinds of other led strips:

| Compare Items | Silicon Neon strip | Silicon glue strip | PU glue strip | PVC neon strip | Silicon Tube strip |

| Colloidal transparency | 95% | 98% | 98% | 95% | 90% |

| Colloid elongation at break | 500% | 100% | 100% | 100% | 100% |

| UV resistant | Excellent | Excellent | Not good | Not good | Normal |

| High and low temperature resistance | -60 ℃ -300℃ | -30℃-150℃ | -10℃-80℃ | -60℃-300℃ | -60℃-300℃ |

| Resistance to weak acid and alkali salts | Good | Normal | Not good | Not good | Normal |

| Environmental protection | Food grade | Normal | Not good | Not good | Normal |

| Thermal conductivity | 0.3-0.5 | 0.2 | No | No | 0.3-0.5 |

| Colloidal hardness (Shore A) | 70-80 | 30-50 | 50-60 | More than 80 | 70-80 |