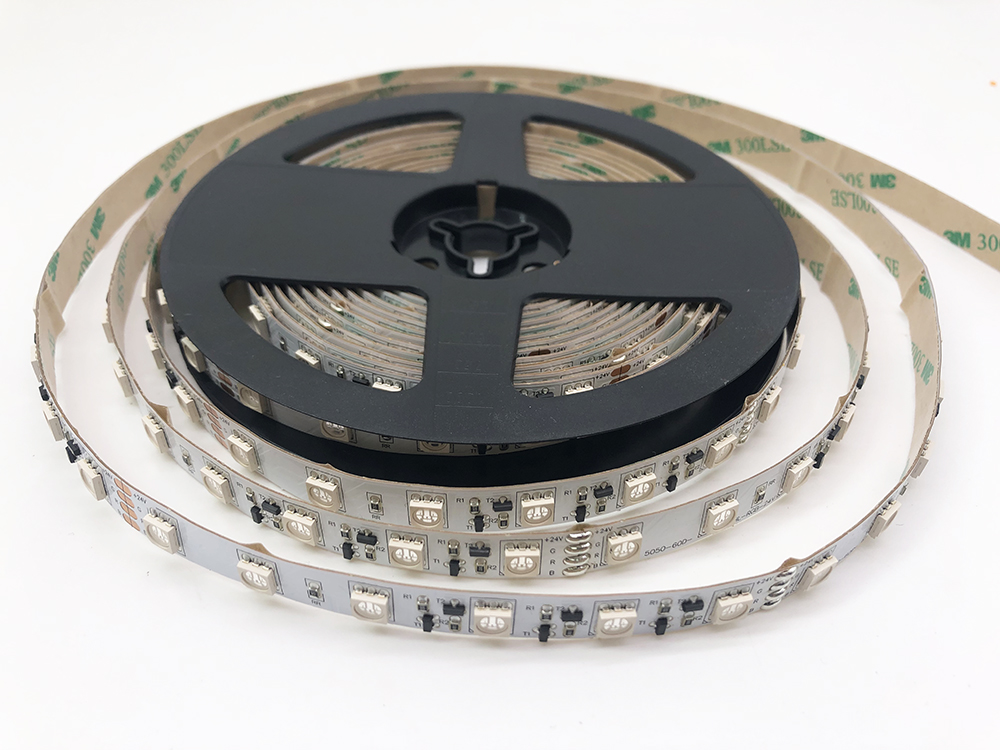

High Brightness 5050RGB Constant Current Flexable led strip

1.Source by high brightness 5050 LEDS and IC for constant current control

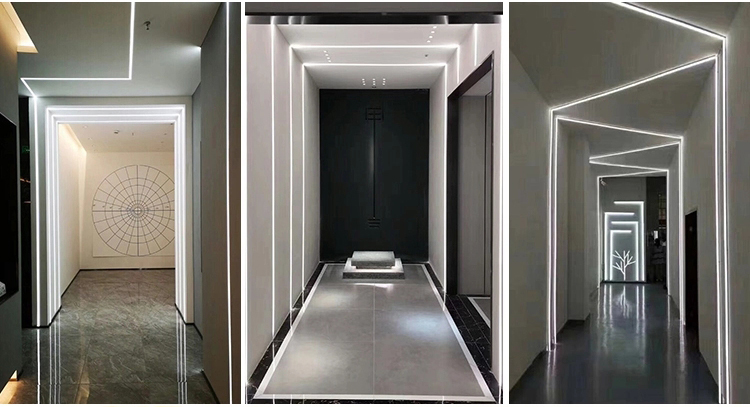

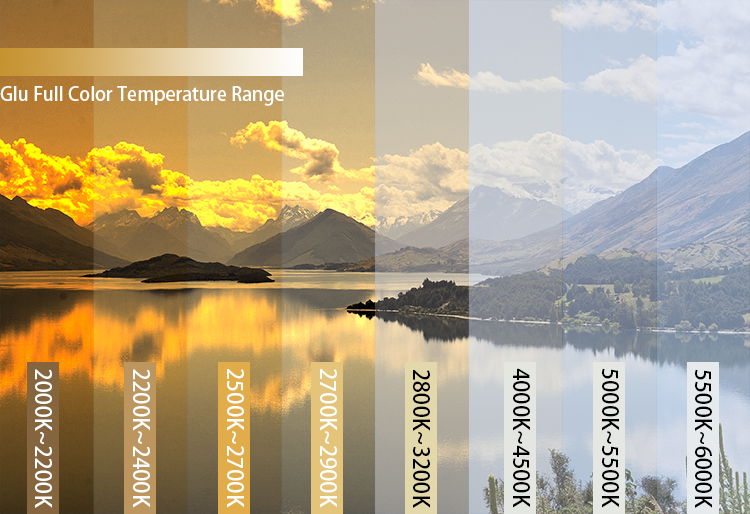

2.LEDS well-distributed on the printed circuit board, better lighting effect and various colors available.

3.High brightness, large viewing angle(120 degree), stable performance, light and flexible shape.

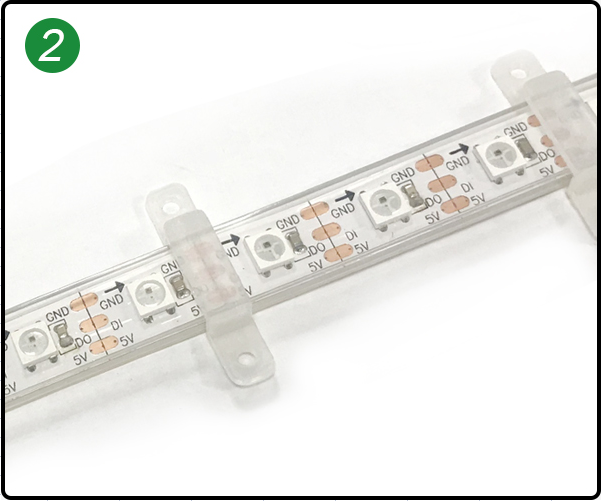

4.High softness and flexibility improve weakness of common led strip lights, realizing easy and reliable operation.

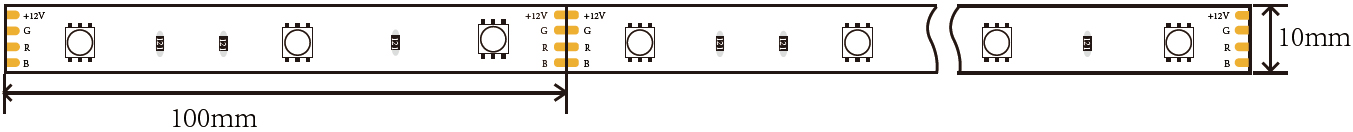

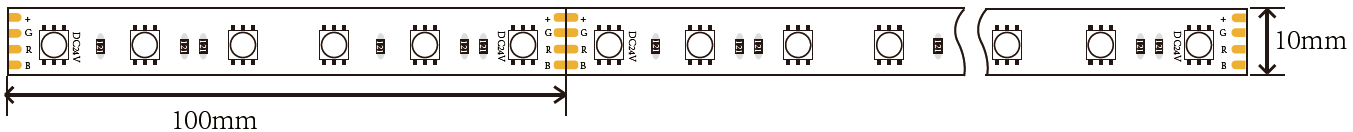

5.Super long 125m, 100m, 60m, 50m, 40m, 30m, 15m for application.

6.Low light decline and long lifespan.

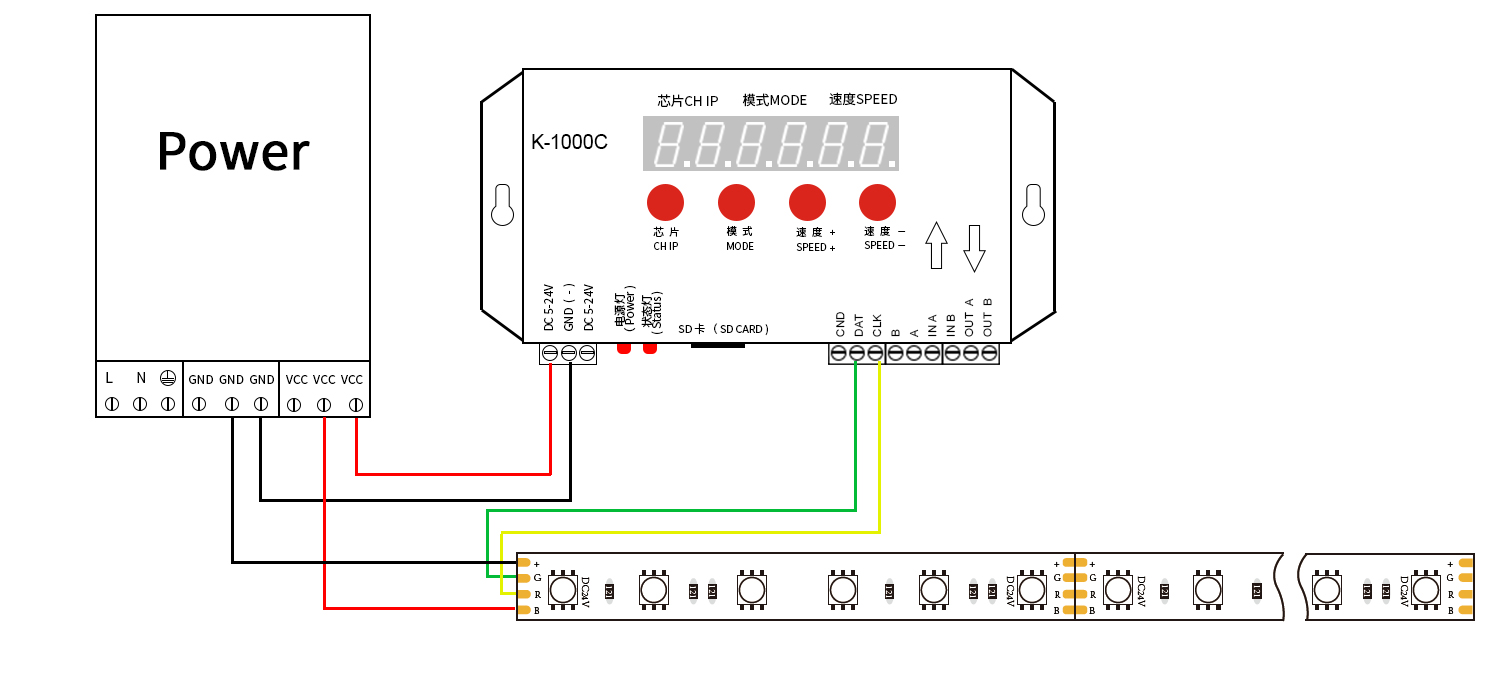

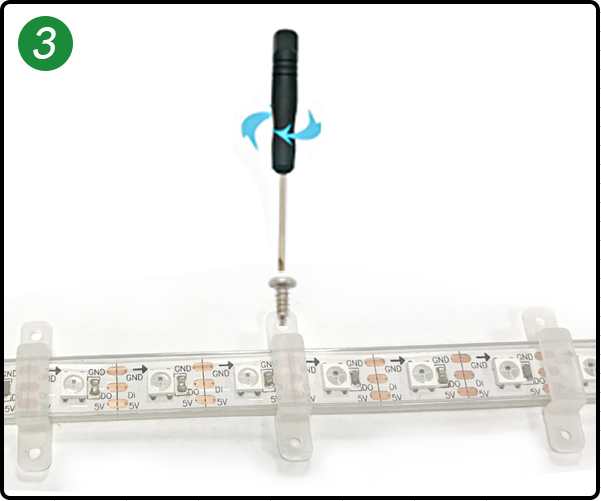

7.DC24V input leads to the easy and safe installation.

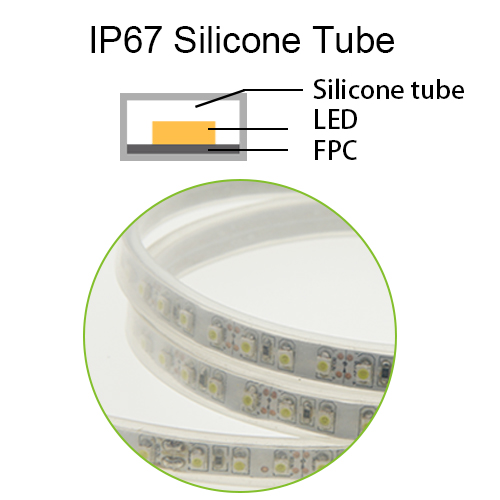

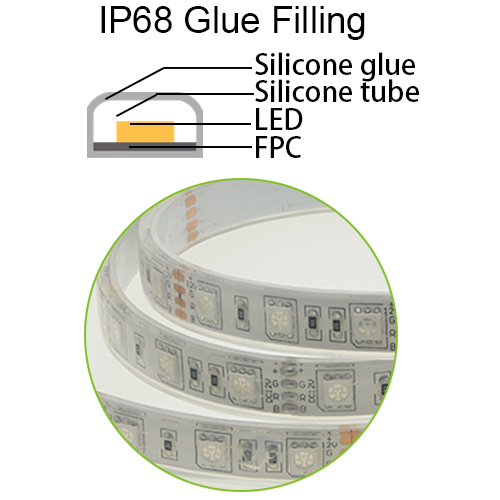

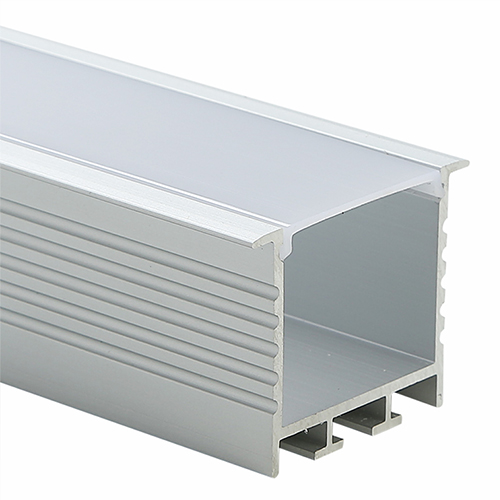

8.IP67/IP68 Waterproof, can be used for indoor and outdoor decoration and edge lighting.