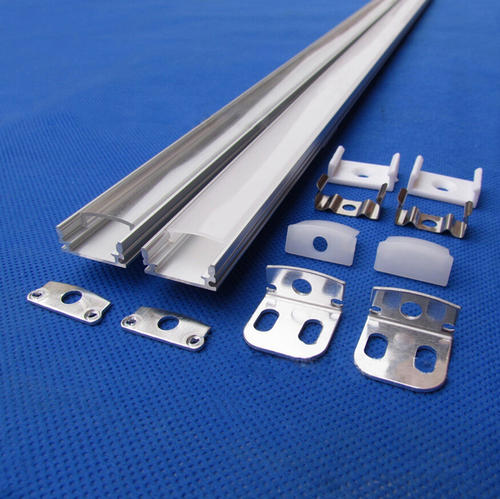

Structure of aluminum profiles:

It is clear from the picture below that the aluminum profiles is composed of the aluminum profile body, end caps, clips, and Cover.

The aluminum profile is used to fit the LED Strip. Have a certain cooling effect.

Cover are called cover also Lens. Covers are generally divided into: milky, clear, diffuse.

End Caps are plastic granules or aluminum flakes at both ends of the aluminum profile. With holes can be put the cable out, without holes can block light.

The clips is used to help the LED Strip fixed mount on the wall.

The role of the aluminum profiles:

In addition to having a certain heat dissipation function for the high-power LED Strip, its biggest feature is to assist the LED Strip to be installed in different places and achieve the best results.

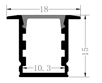

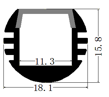

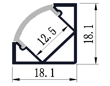

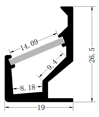

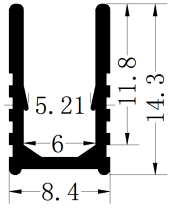

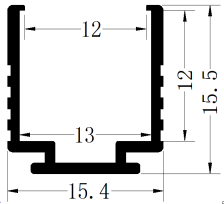

Aluminum profiles size:

There are many sizes of aluminum profiles:

With and without edges:

There are round, triangular and fancy shapes:

We can even make more different sizes if customers need it.

Installation of aluminum profiles:

First clean the inside of the aluminum profiles, then tear off the LED Strip 3M tape, stick it in, add a plug, and cover it with a cover.

Fix the bayonet to the wall with screws, and then fix the aluminum slot to the wall.

The relationship between the size of the aluminum profiles and the LED Strip:

I previously introduced the various performances of aluminum profiles and different LED Strip dot free on another page. See the link for details: https://ledstriplightmanufacturer.com/cob-led-strip

So now we specifically introduce the relationship between different aluminum profiles and the same LED Strip: the deeper the aluminum profiles, the less light spots. Take the same 5050 60pcs led per meter as an example. The 5050 SMD belongs to large-particle lamp beads, which is more prone to flare than the small-particle lamp beads of 2110; and the LED Strip lamp beads of 60pcs per meter are not high in density and easier to Light spot. Then is there no way to achieve the effect of dot free? The answer is no, the LED strips of 5050 60 lamps will have different light spots when placed in aluminum profiles of different sizes. The farther the LED Strip is from the mask, the smaller the flare.

Type of aluminum profiles:

Used for ordinary low-voltage LED Strip; this type of LED Strip is a small size LED Strip with a cover

Neon LED Strip: It is mainly to assist the installation of Neon LED Strip, so they are some large sizes as follows, because Neon LED Strip itself is glue-molded, so there is no cover for this type of aluminum profiles:

Color of aluminum profiles:

The color of the aluminum profiles is usually silver and black. It can also be oxidized according to customer requirements

Application of aluminum profiles:

Wine cabinet, cabinet, shopping mall, home, furniture, cinema, stairs, walkway.

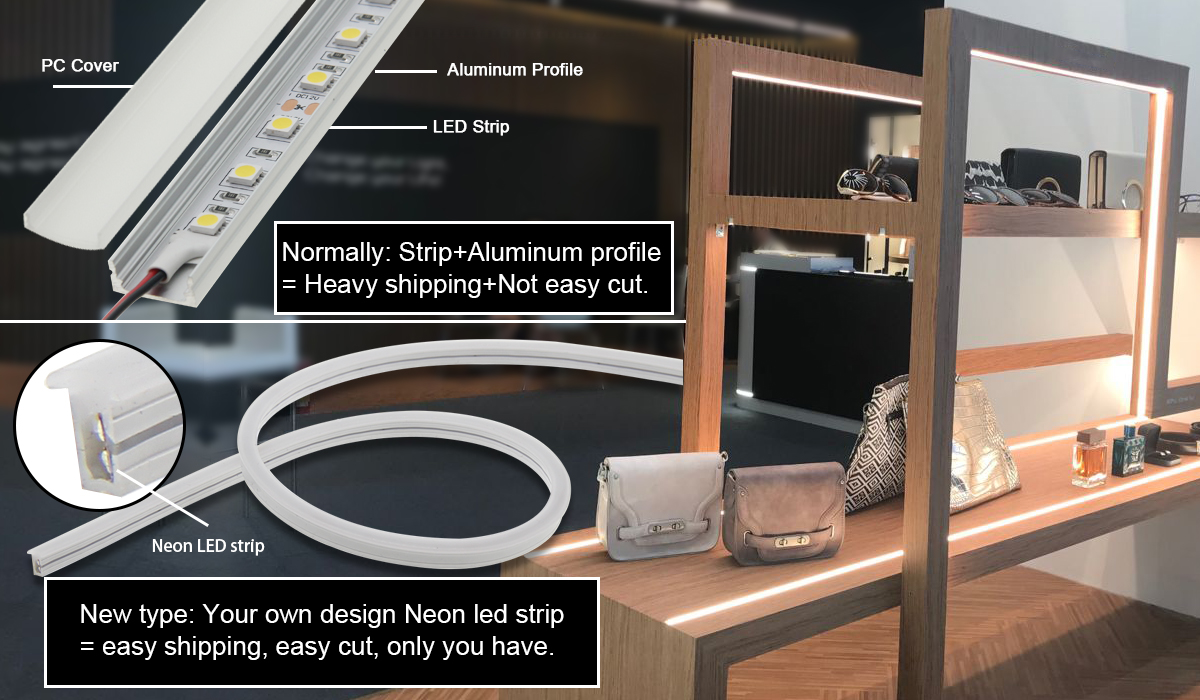

Aluminum profiles VS Neon LED Strip

The LED Strip on the cabinet below is taken as an example. Normally, the LED Strip is pasted on the aluminum profile, and then the PC cover is inserted into the aluminum profile. The advantages of this are: the price is relatively cheap, the disadvantage is: it is not conducive to transportation and cutting. For example, when the customer needs a longer aluminum profiles, it will be difficult to transport more than 2M, and the transportation cost will be very high.

Now there is a new way to help solve this problem: use neon LED Strip to make the corresponding shape. This way you can directly embed the LED Strip into the required object. The advantage of this is: it can be made into 5M Rolls are convenient for transportation; the silicone is resistant to yellowing and will not turn yellow for a long time; it can be cut to the size required for convenience; it can also be bent without the need for additional corners; the disadvantage is that the price is slightly more expensive.