Product Features:

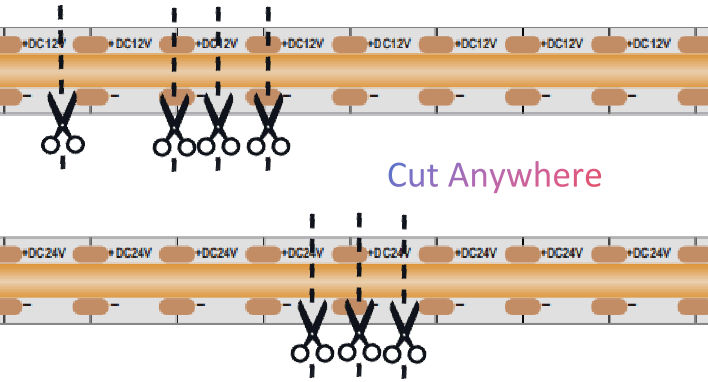

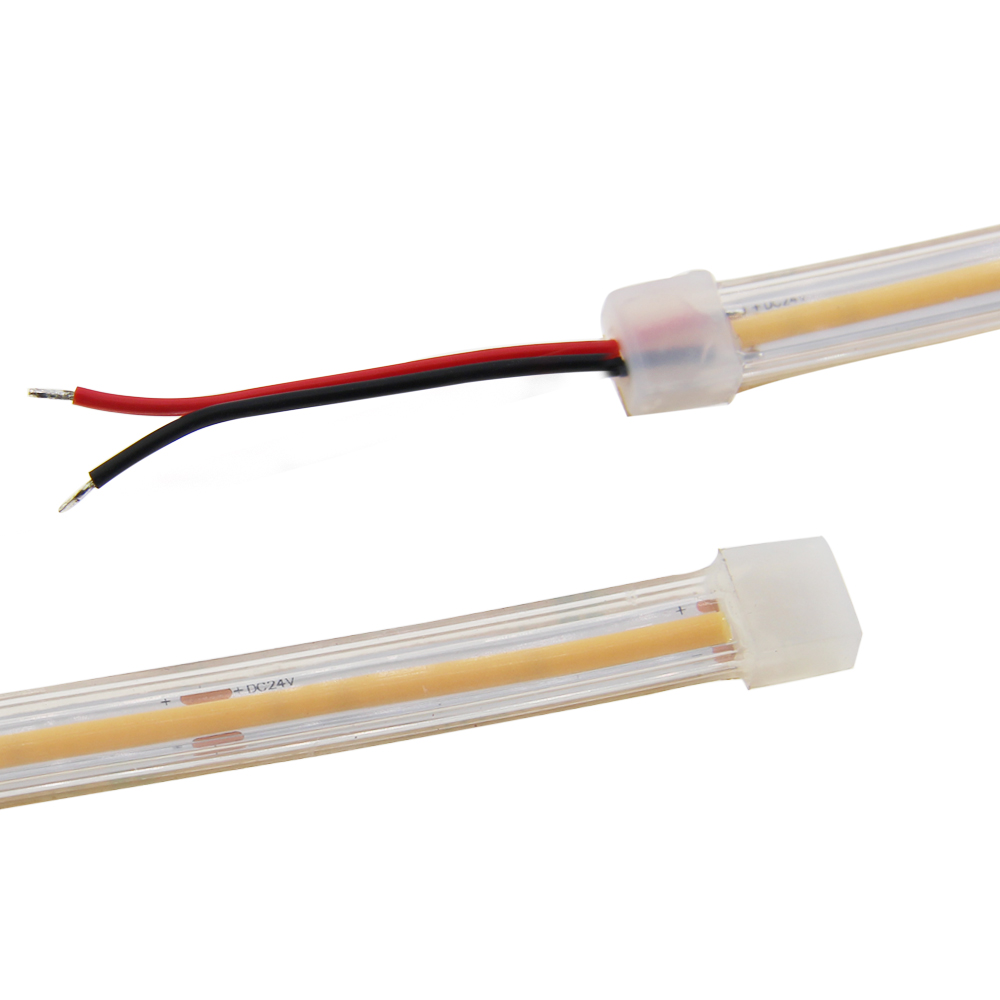

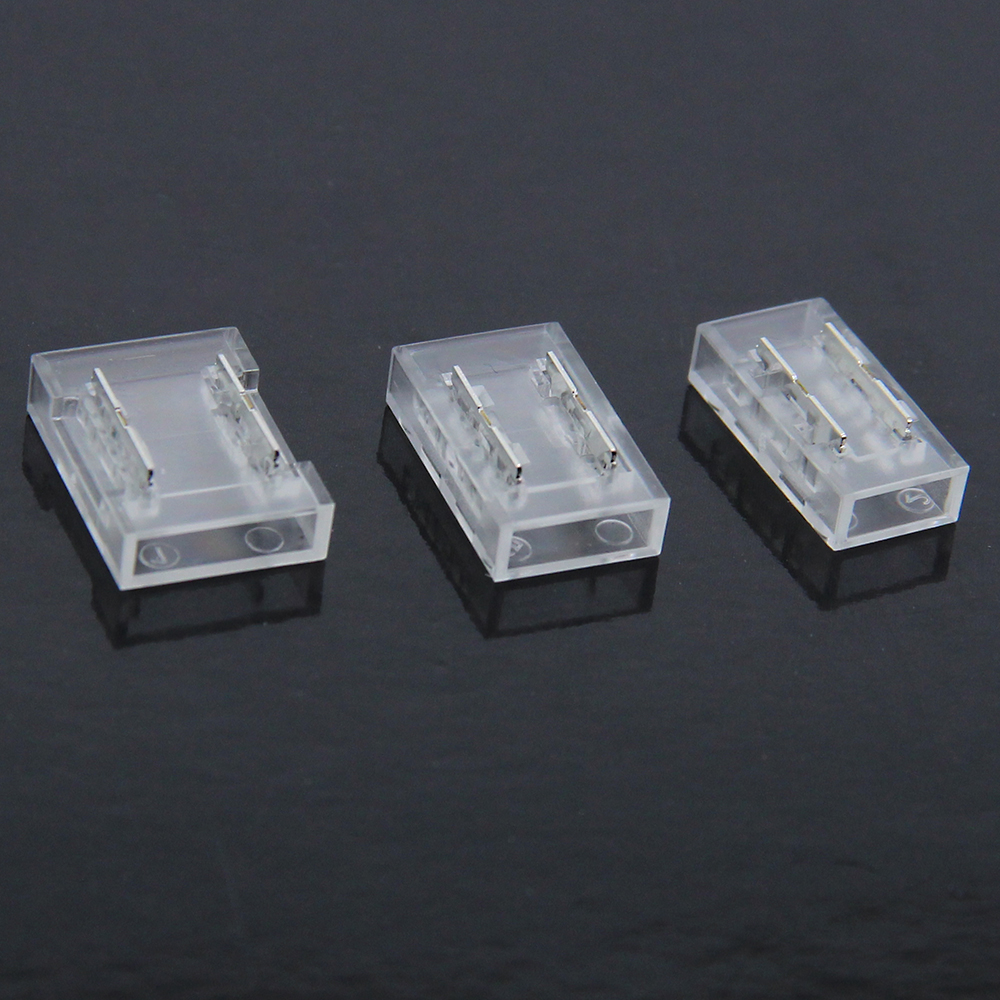

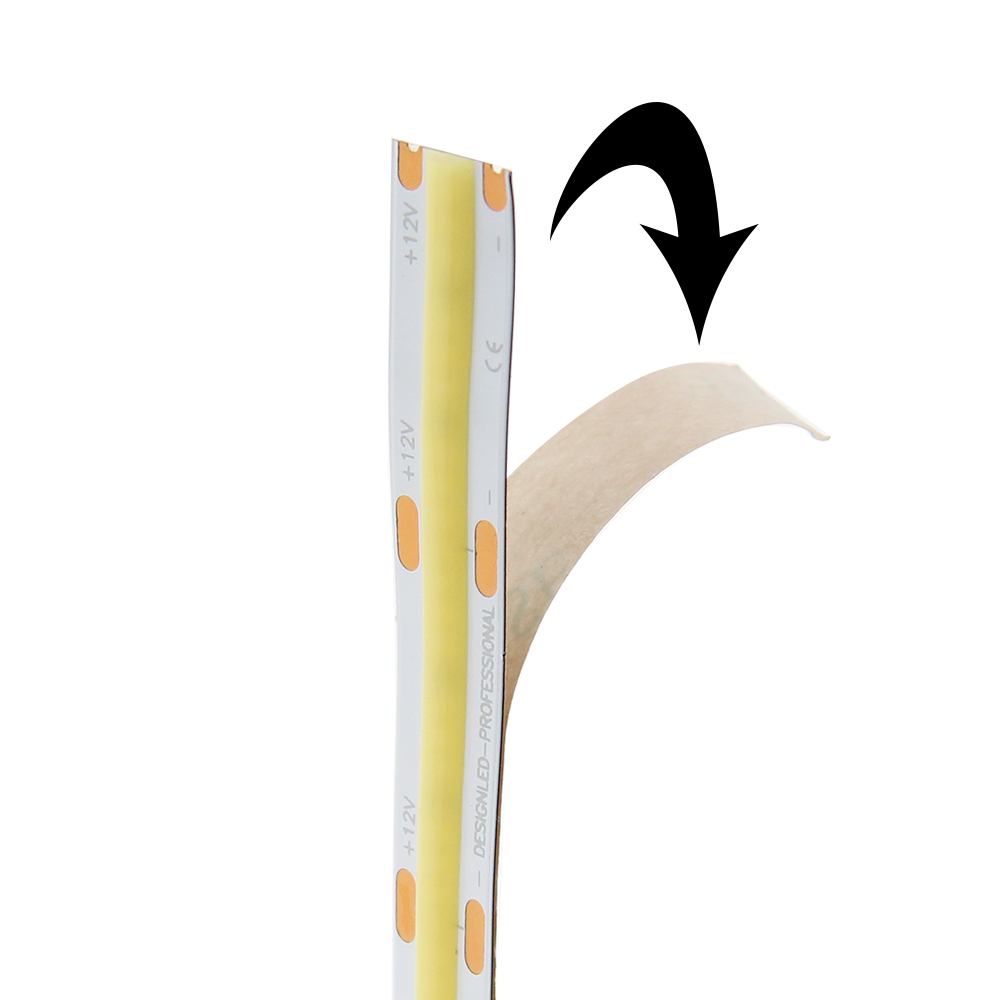

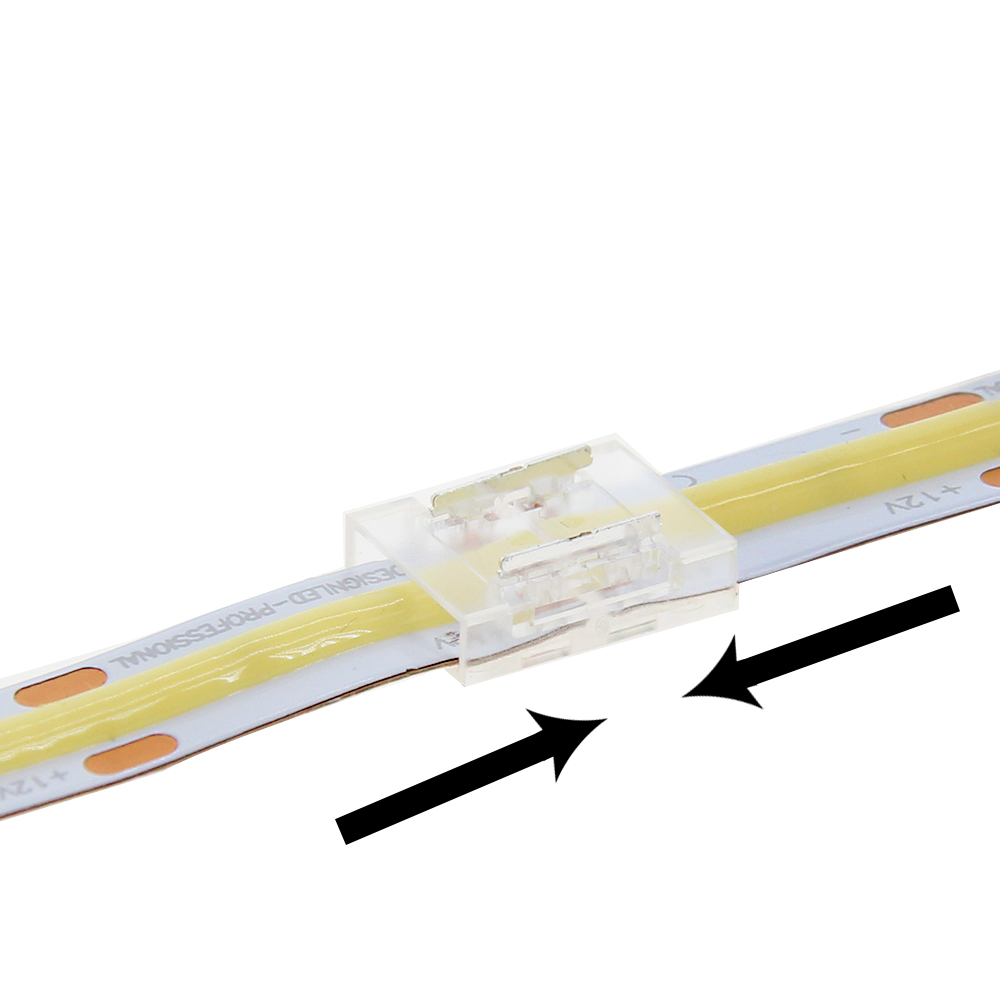

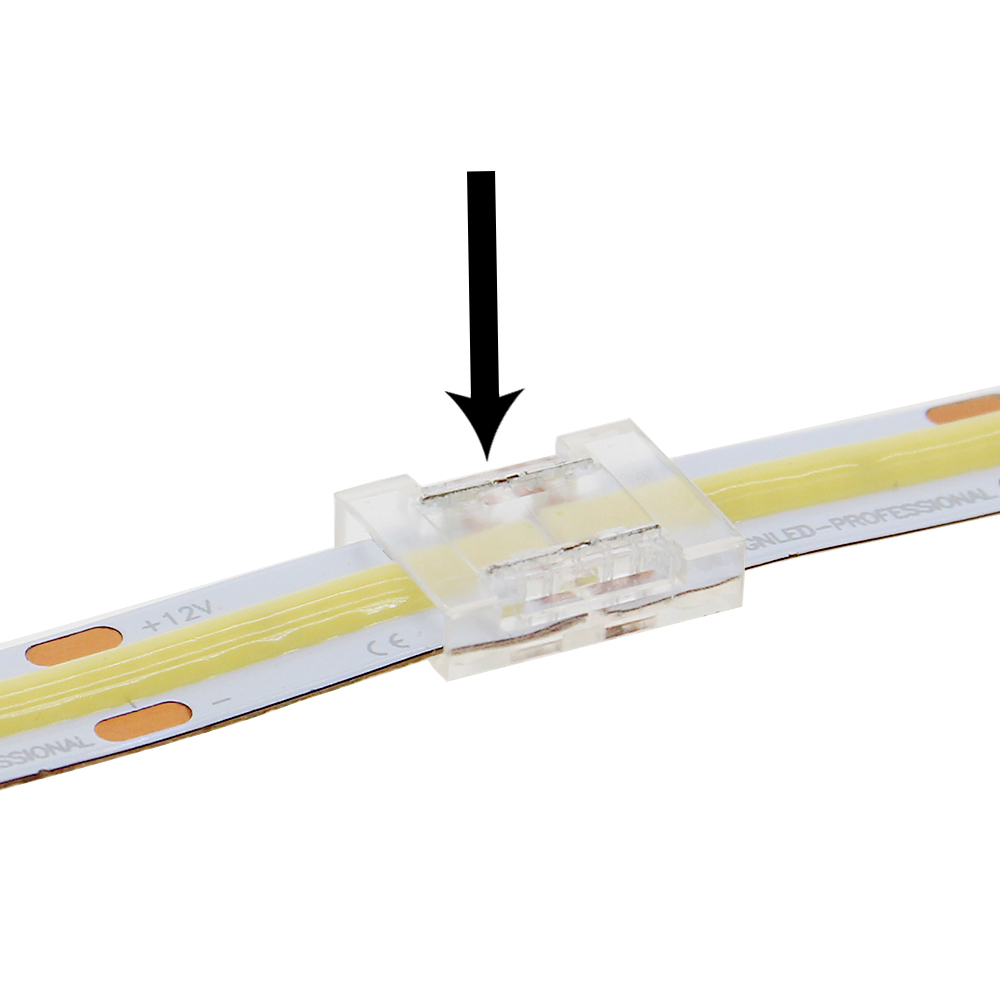

●Any cut, easy to use, more accurate installation

●The led strip will work well after each unit been cut and will not affect other leds work;

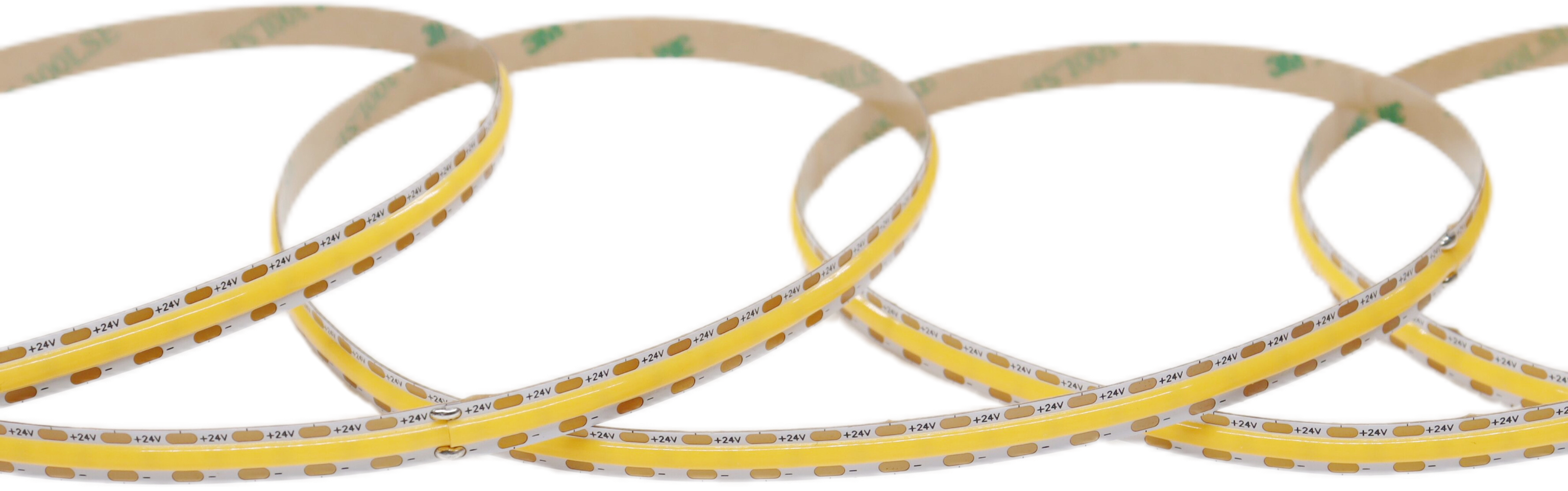

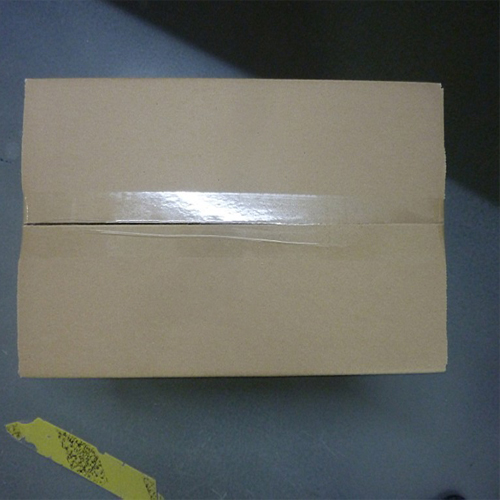

●High-quality double-sided copper FPC board,Easy to Install and Preserve;can Be Bent Freely;With 3m

Adhesive Tape On the Backside.

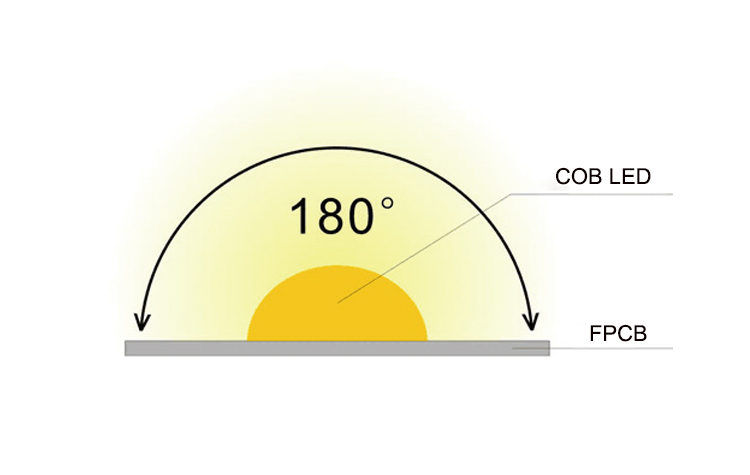

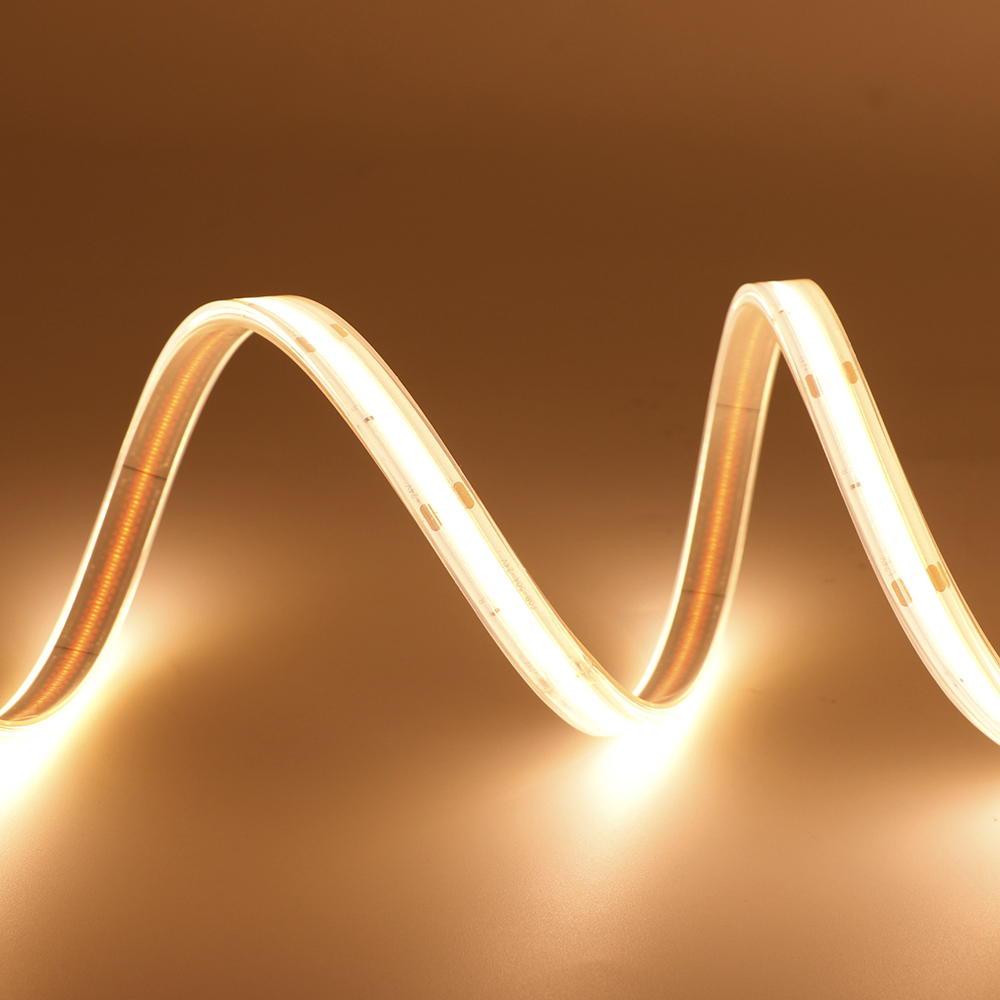

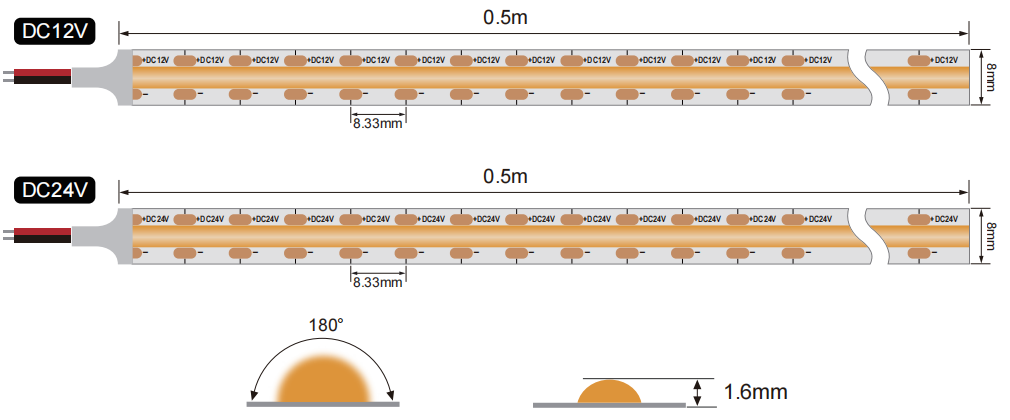

●High-density COB chips, soft light and brighter light

●180° ilumination angle, high CRI, no spot, no flicker

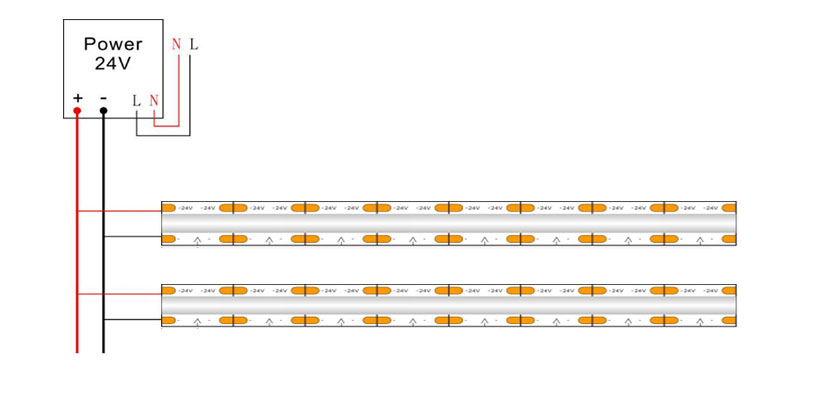

●As a manufacturer, we can customize different lengths,

board width, voltage, power, color temperature and color

rendering index according to customer requirements.