Product Features:

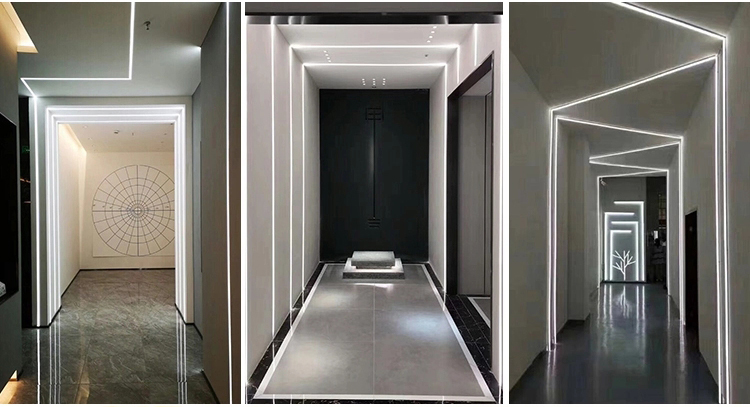

LED strip light is used in a variety of ways both as practical lighting and feature lighting. Many projects require a high lumen light source and therefore require the bright enough LED strip light . These LED strip light operate at a high wattage to produce a larger amount of lumen per meter.

High Lumen LED strip lights are often used as the primary source of light in a room to replace traditional lamps. These LED strip lights can be recessed and suspended using the Aluminum profile to create a professional lamp.

As a star company ,we keep a variety of High Lumen LED strip light suitable for a range of installations. Shop our selection of High brightness LED strip lighting now and find the perfect product for your lighting installation.

Product Specifications:

| Part NO. | A0240 | A0241 |

| LED | 2835 | 2835 |

| Quantity | 240leds/m | 240leds/m |

| IP Rank | IP20 | IP20 |

| Color | cw ww | cw ww |

| PCB Color | white | white |

| CRI | CRI>80 | CRI>95 |

| Power | 24W±10%/m | 24W±10%/m |

| Lumen | 3900lum/m | 3000lum/m |

| Dimension | 5000*15*2mm | 5000*15*2mm |

Product Details:

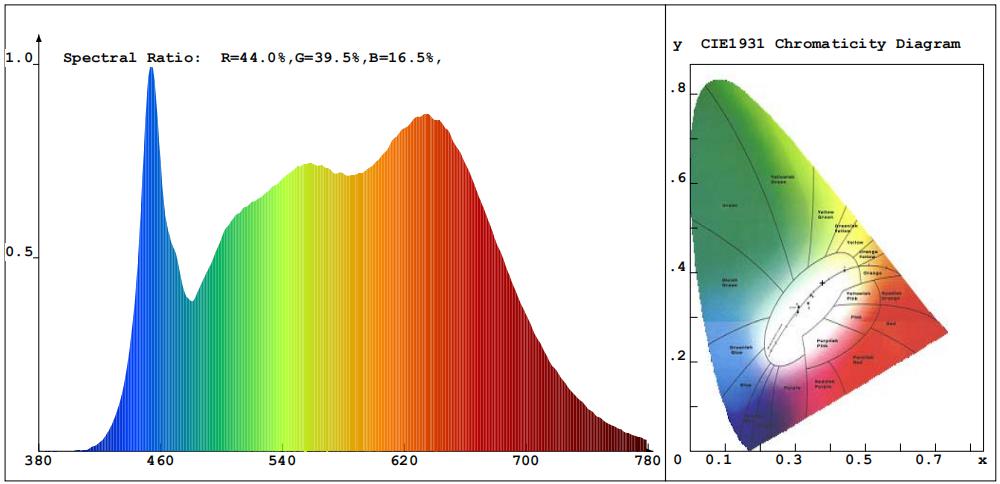

LED Test Report

Product Mark

Product Type :24V 240led/m 4000K Manufacturer :LEDWORKER

Temperature :25’C Humidity :65%

Operator :J Test Date :2020-12-21

Chroma Parameters

Chro.Coor.: x=0.3771 y=0.3770 u=0.2228 v=0.3341 duv=0.0011

CCT: Tc= 4095K Dominant Wave.: 579.1nm Purity: 26.3%

Flux Ratio: R=20.1%,G=76.9%,B=3.0% Peak Wave.: 453.4nm Half Width: 25.7nm

Rending Index: Ra= 97.5

R1 =98.6 R2 =99.7 R3 =96.9 R4 =97.2 R5 =96.8 R6 =96.2 R7 =97.7

R8 =97.2 R9 =97.9 R10=97.2 R11=98.0 R12=73.9 R13=98.9 R14=97.7

R15=0.0

Photo Parameters

Flux: 3032.75lm Effi.: 113.7lm/W Radiant: 12034.0mWIv: 0.0mcd

Ele. Parameters

Forward Current:If=1116.0mA Forward Voltage:Vf=23.90V

Reverse Voltage:Vr=5.00V Reverse Current:Ir=0.00uA

Instrument state

IntgeTime: 25.343ms VPeak: 13750 VDark: 1023

Scan Range: 380-780nm

Please Caution

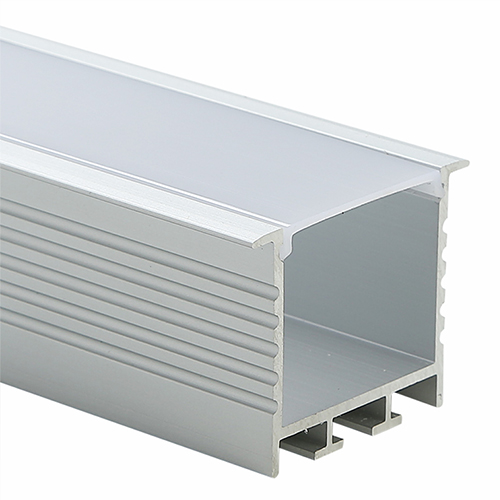

High Lumen LED strip light operates at a higher wattage and consequently produces more heat than the standard strip light . To prevent the LED strip light from overheating they must be installed within an Aluminum profile for heat dissipation.

When installing the LED strip within the profile, it is important to avoid excess strain on the led strip to prevent any damage. This can be done by using a dry cloth or other soft to press the led strip in place to reduce pressure when installing.

High wattage LED strip light requires a power supply capable of supplying the power required. All the LED drivers should be run at no more than 75% of its capacity to prevent overheating.

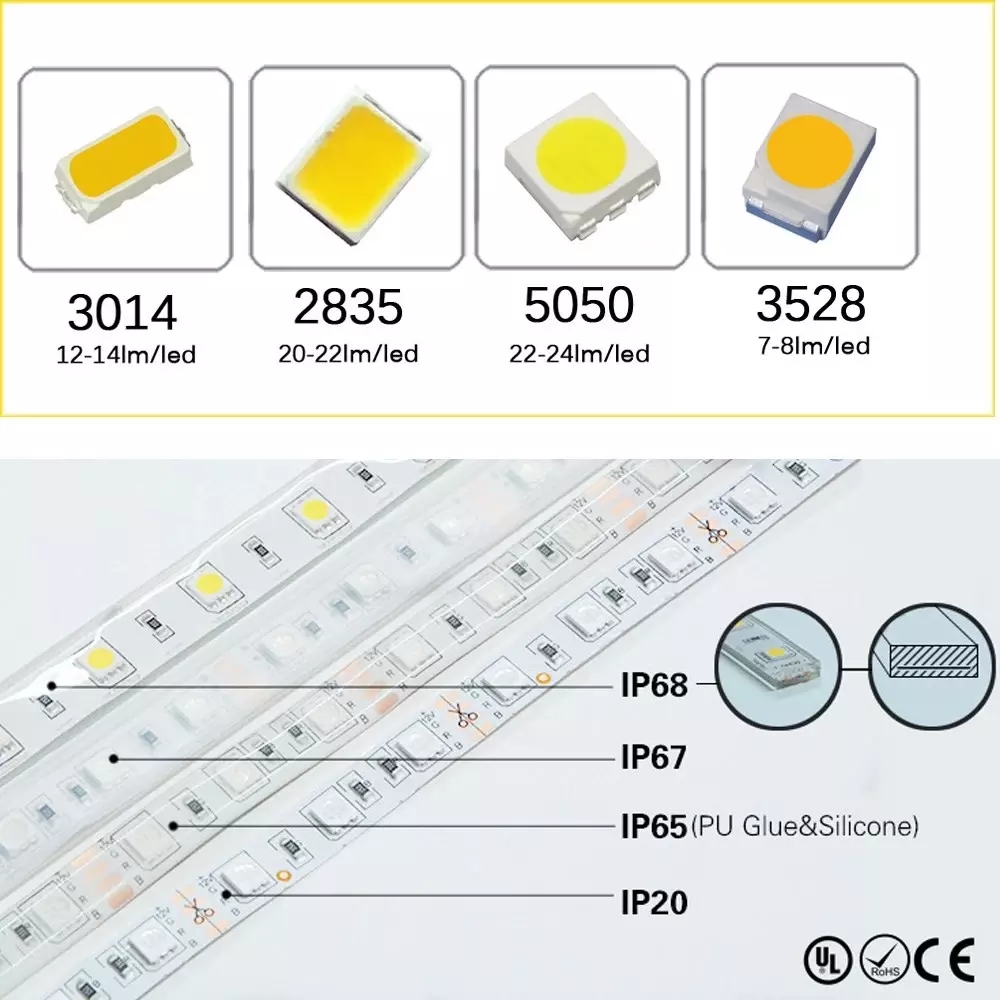

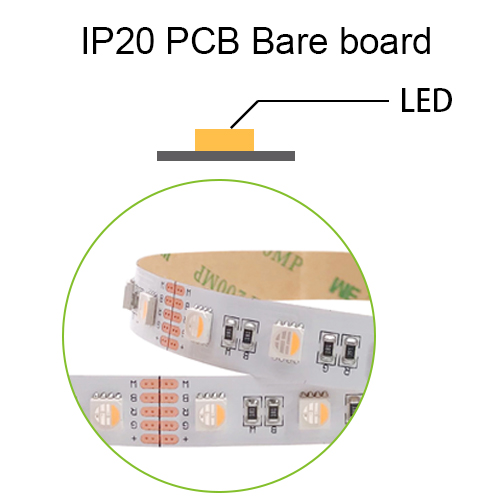

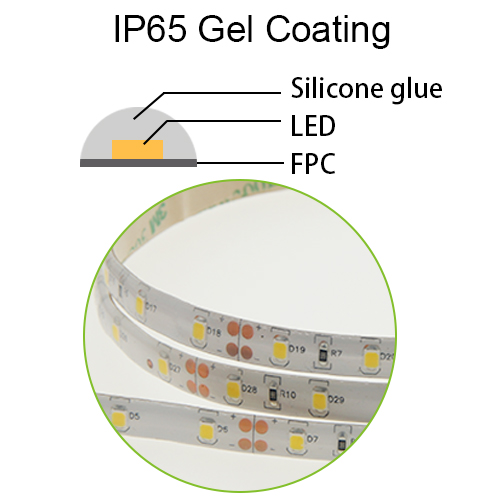

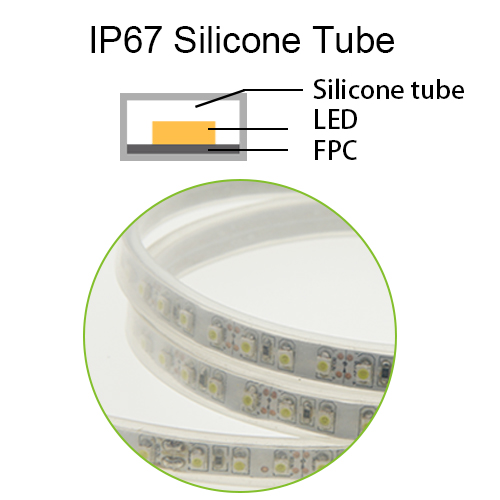

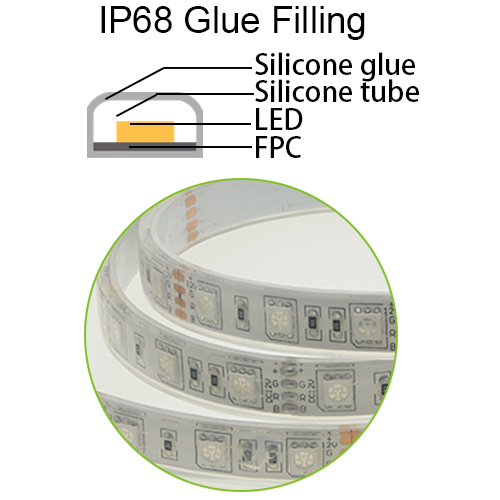

Waterproof Level:

Applicable to Dry Environment

Applicable to Wet Environment

Applicable to Water Environment

Applicable to Flooded Environment

Easy to Use and Easy to Install

Tear Off the Adhesive Tape

Paste to Where You Need to Install

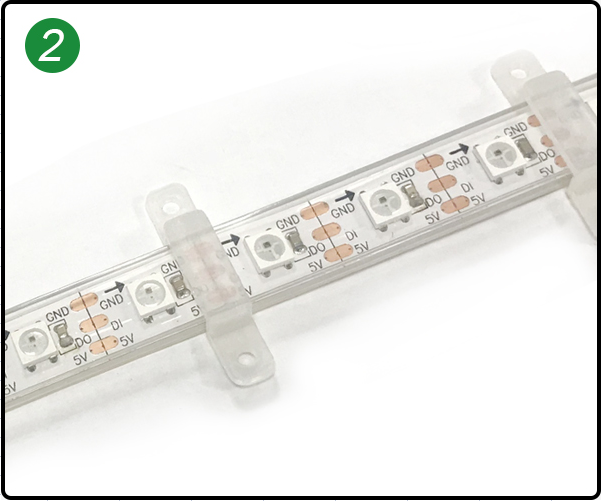

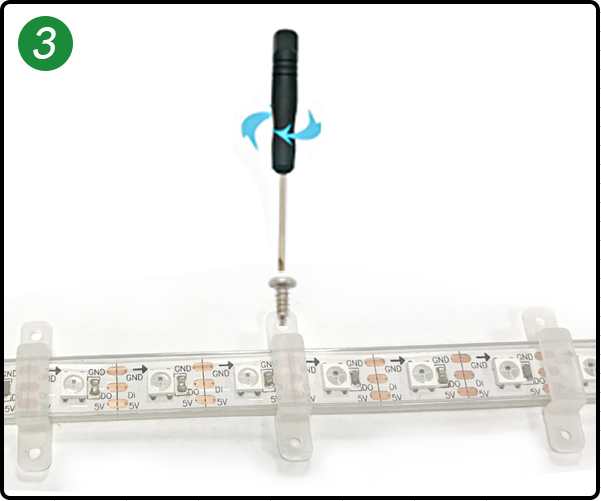

(2) Snap-on Installation:

This Installation Method is Suitable for the Casing Waterproof Product.

The Product is Fixed by the Screw Transparent Buckle to Make the Installation Firmer.

Accessories (Clips+Screw+Screwd-Diver)

Put the Clips on the Strip

Fixed the Clips

Hippo Buckle

Controller

Aluminum Trough

Power Supply

Application Scenario:

Packaging:

Box Size: 43*43*35cm 100 reels per box

Weight: IP20: 12KG

5 of the Most Common Customer Questions (FAQ)

High CRI strips are generally not waterproof with glue, because the glue for waterproof glue is silicone, which will slightly change the color of the light strip and change the display index of the light strip. Therefore, it is not recommended for the strip to be waterproof with IP65 glue, and the casing and extrusion glue are good choices, which can achieve the waterproof function without affecting the CRI.

The High CRI led strip can be cut like other SMD strips. Cut according to the position of the scissors.

The service life of High CRI led strip is the same as that of ordinary LED strip, which is 50,000 hours.

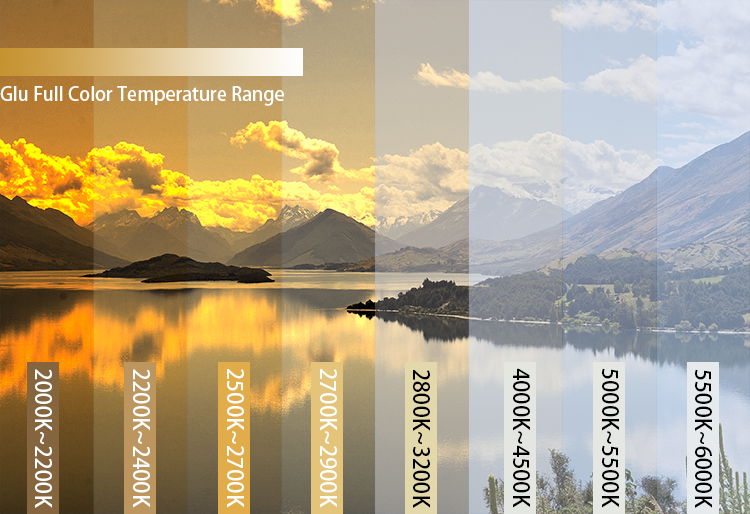

High CRI > 95. Color: 2600-2800K 2900-3200K 3800-4300K 5000-5500K 6000-6500K

(1) Paste Installation:

This Installation Method is Generally Used for the Waterproof Environment,

And the High-Viscosity 3m Adhesive is Attached to the Back of the Lamp Strip,

Which Can Be Directly Pasted on the Required Solid. The Surface of the Media.

(2) Snap-on Installation:

This Installation Method is Suitable for the Casing Waterproof Product.

The Product is Fixed by the Screw Transparent Buckle to Make the Installation Firmer.