Product Features:

*Flip-chip

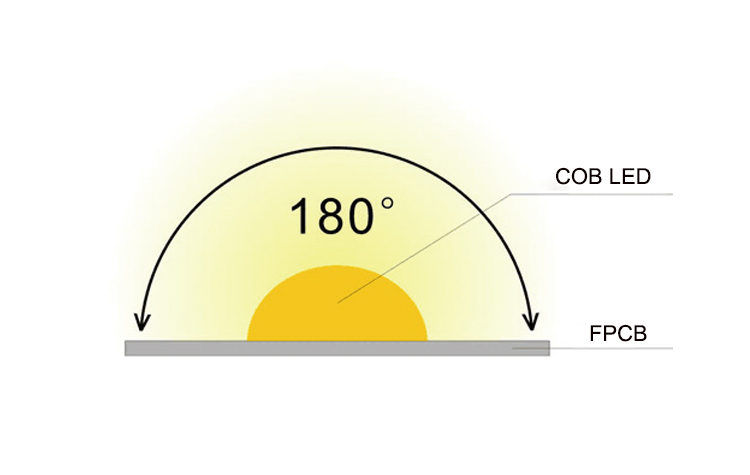

*Beam angle 120 degree

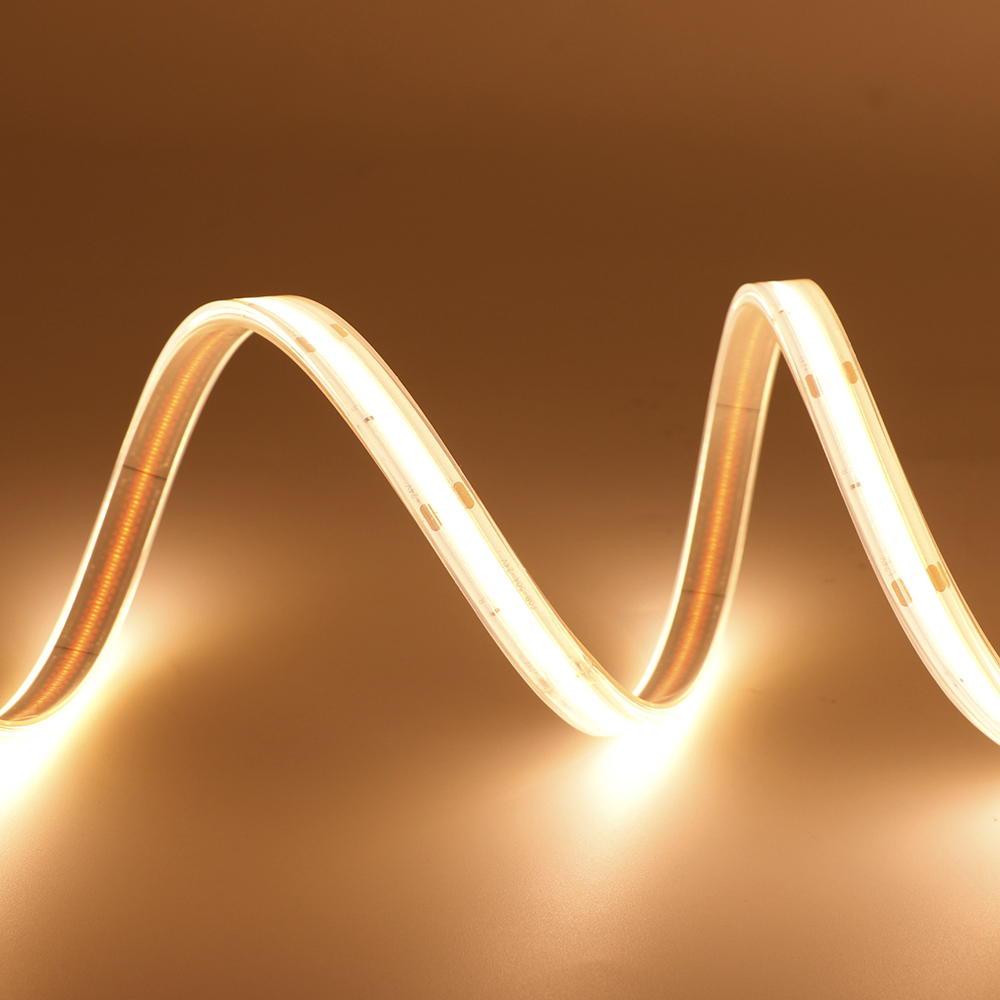

*High density LED,no light spot

*Homogeneous illumination

*Extremaly flexible

*New tech against traditional strips

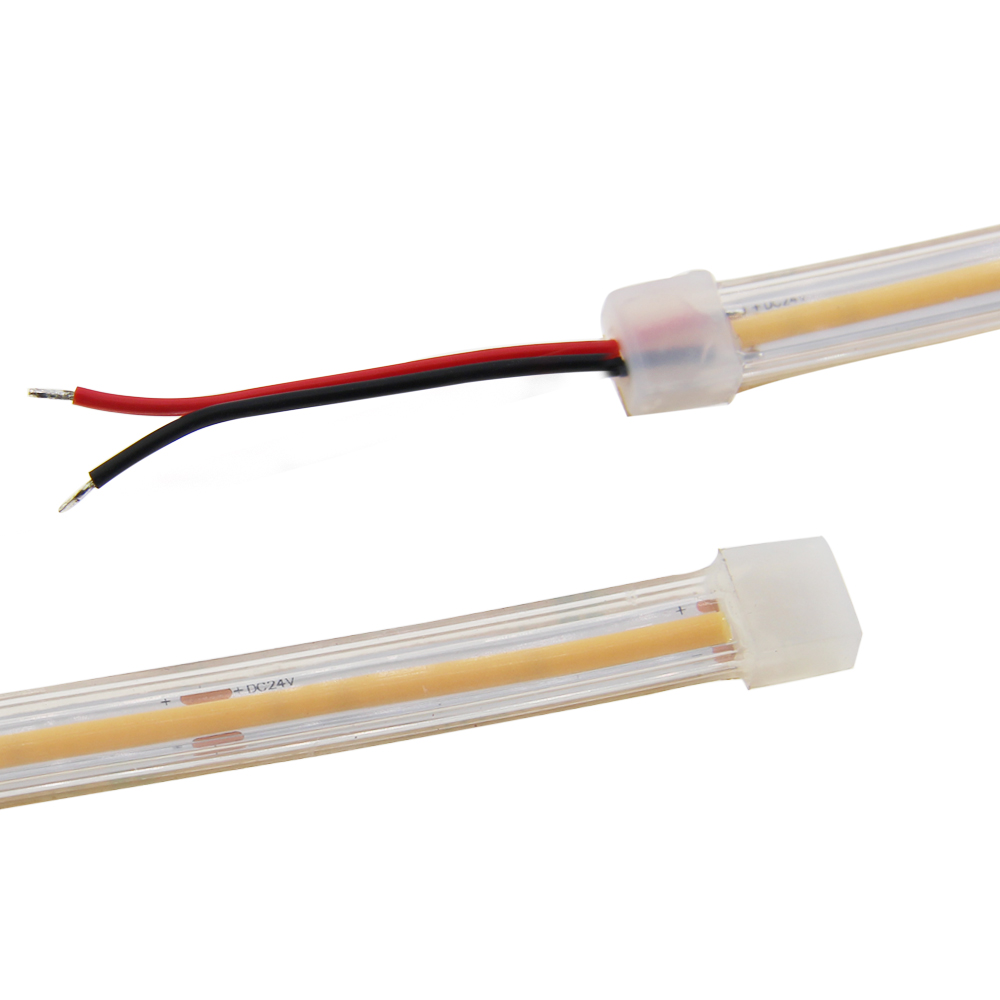

* 3M 300LSE adhesive tape for easy intallation.

* Standard 5M on reel,also could make 10M, 20M one reel.

* CE,RoHS, 3 years warranty.

* Different waterproof grade can meet requirements in different environments

COB led strip specification

The COB led strip is a very good used for cover, Cabinet & Furniture soffit lighting, showcase and display path and contour making. Edge, and back lighting.

| Advantage: |

Side Emitting RGB |

| Model No. |

LW-COB025 |

| LED Qty: |

630pcs per meter |

| Color |

RGB |

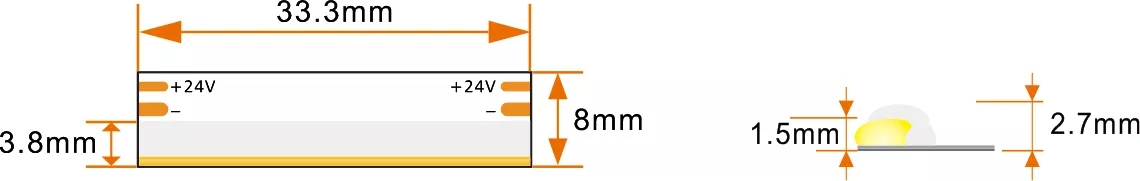

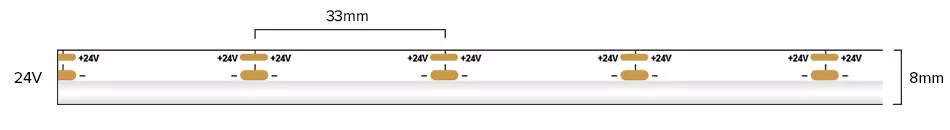

| PCB Width IP20: |

8mm width |

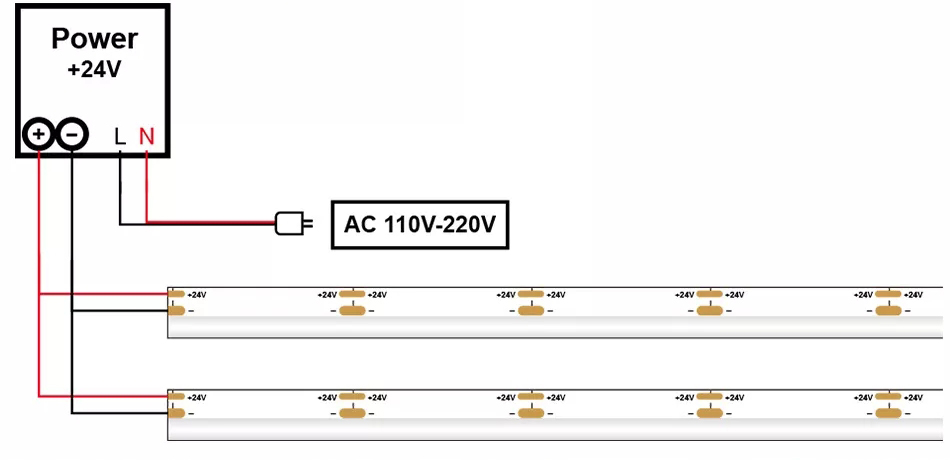

| Input Voltage: |

DC24V |

| Watts: |

9.6W |

| Luminous Flux: |

30LM / W |

| Weigh/ Reel: |

125g |

| PCB color: |

White |

| IP Grade: |

IP20 |

| Operating temperature: |

.-25 to 45℃ |

| Beam angle: |

120 degree |

| Certification: |

CE; RoHS |

| Max Run: |

5M |

| Min Run: |

24V 33.3mm |