LED strips are favored by more and more product manufacturers because of their small size, flexible, rich colors, bright colors, easy cutting and environmental protection. People are no longer limited to only using LED strips in shopping malls, interior decoration, KTV, bars and other places. More and more people apply LED strips to their products, such as: mirror headlights, TV sets, robots, coffee machines, water dispensers, furniture, etc.

As a professional LED strip supplier, more and more customers are discussing with us the needs of various special customized products. So what should be considered when customizing LED strips to meet the application of LED strips in products?

Several misunderstandings about LED strips:

Before customizing a strip light suitable for our own products, we need to know several major misunderstandings that may occur when customizing led strips. Clarify the understanding in order to better issue customized requirements:

● The more SMD, the higher the brightness

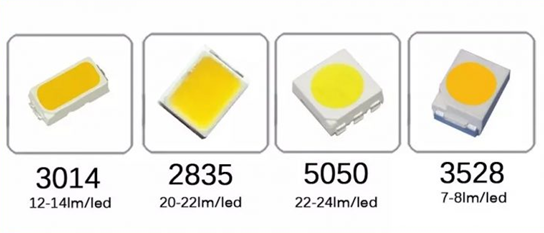

Lamp beads of different sizes have different single brightness. If you use lamp beads of the same brightness level, according to common sense, it is true that the more lamp beads, the higher the brightness. Take the double-row 2835SMD 240 light led strip as an example (https://ledstriplightmanufacturer.com/high-cri-led-strip-manufacturer): 24V input, single lamp bead 0.2W, theoretically we can do: 0.2W x 240 = 48W. When the current is too large, the PCB board can’t withstand too much temperature, and more light energy is converted into heat energy, and more heat energy will damage the life of the lamp beads. Therefore, as a professional led strip manufacturer, we will limit the current that the PCB board can withstand, and limit the maximum power of the SMD light bar to 18-22W.

● Lux value is low so LM value is also low?

Before talking about the relationship between LUX and LM, let’s first understand the specific concepts of LUX and LM. From Wikipedia we know (https://en.wikipedia.org/wiki/Lux)

The lux (symbol: lx) is the SI derived unit of luminance, measuring luminous flux per unit area. It is equal to one lumen per square meter. In photometry, this is used as a measure of the intensity, as perceived by the human eye, of light that hits or passes through a surface. It is analogous to the radiometric unit watt per square meter, but with the power at each wavelength weighted according to the luminosity function, a standardized model of human visual brightness perception. In English, “lux” is used as both the singular and plural form. The word is derived from the Latin word for “light”, lux.

Illuminance is a measure of how much luminous flux is spread over a given area. One can think of luminous flux (measured in lumens) as a measure of the total “amount” of visible light present, and the illuminance as a measure of the intensity of illumination on a surface. A given amount of light will illuminate a surface more dimly if it is spread over a larger area, so illuminance is inversely proportional to area when the luminous flux is held constant. One lux is equal to one lumen per square metre: 1 lx = 1 lm/m2 = 1 cd·sr/m2.

Then LUX is related to the surrounding environment, distance, area and LUM is the sum of light. As a professional LED manufacturer, we use Spektron coating integrating sphere to test the LM value. So it’s not that LM and LUX can’t be completely equal. The following is a video of how to test as a professional LED strip factory:

Illuminance is a measure of how much luminous flux is spread over a given area. One can think of luminous flux (measured in lumens) as a measure of the total “amount” of visible light present, and the illuminance as a measure of the intensity of illumination on a surface. A given amount of light will illuminate a surface more dimly if it is spread over a larger area, so illuminance is inversely proportional to area when the luminous flux is held constant. One lux is equal to one lumen per square metre: 1 lx = 1 lm/m2 = 1 cd·sr/m2.

● The higher the power, the higher the brightness

Generally , the higher the power, the higher the brightness. The same constant voltage led strip, when the voltage is constant, continuously adjust the current, his power will continue to increase, and the brightness will be proportional to it. But brightness isn’t the only condition we’re after. The increasing current makes the led strip get hotter and hotter, and the temperature is high enough to damage the life of the led strip. Therefore, engineers will make high-brightness and stable high-brightness light bars according to the brightness requirements. The methods of improving the brightness of the led strip are roughly as follows: widening the width of the PCB board to allow more current to pass; increasing the thickness of the copper foil of the PCB is also to allow the current to pass smoothly; using brighter lamp beads to make a brighter ‘s led strip. For example, there are: 110LM led strip per watt, and 170-180LM led strip per watt; adding more light beads per meter led strip; or helping the led strip to dissipate heat. All in all, it is not necessary to increase the power to achieve the purpose of increasing the brightness. A more suitable product can be designed according to the needs of the product application.

● Expectations of actual service life are too high

LED manufacturers expect LED lifetimes to be 100,000 hours MTBF (Mean Time Between Failure, the standard used by traditional luminaries manufacturers to measure the lifetime of light sources). But like all basic light sources, the luminous flux lumens of LED also decay over time. So while LED can last a long time, MTBF is not the only consideration in determining lifetime. The attenuation of LED lumens is affected by many environmental conditions such as ambient temperature, humidity and ventilation. Lumen decay is also affected by control, thermal management, current levels and many other electrical design considerations. As a light source for lighting, the brightness of the lamp has a process of gradually decaying and dimming (such as fluorescent lamps, energy-saving lamps), which is referred to as light decay. On application-level LED, when the light decay exceeds 50%, the human eye can clearly feel the change in brightness. At this time, the product brightness is not suitable for lighting. To sum up, what we should pay attention to when purchasing LED is its light decay speed, not usage time.

● Treat the actual lighting angle as the effective angle.

The light-emitting angle of SMD LED is divided into effective angle and actual light-emitting angle. The angle between the direction where the luminous intensity value is half of the axial intensity value and the luminous axis (normal direction) is the effective angle. 2 times the half-value angle is the viewing angle (or half-power angle) is the actual light-emitting angle. Angles other than half of the axial intensity are not counted as effective angles in practical applications because the light is too weak. When purchasing products, we should pay attention to the actual light-emitting angle of the product. When calculating the number of products used in the project, the actual light-emitting angle shall prevail, and the effective light-emitting angle can be used as a reference value.

Custom LED Strip process:

● Clear your needs:

Whether it is an projector or a product manufacturer, before communicating with the led strip manufacturer about the customized led strip required, it is necessary to know their own needs, including: Where does the led strip need to be used? Requirements for the use environment? For product size requirements? Requirements for brightness? For color requirements? Requirements for service life, etc. If you can come up with design drawings or similar videos, it is the most intuitive method.

● Communicate design with factory:

When the sales staff understand your specific requirements, they will discuss specific plans with the engineering team, including: what kind of lamp beads to use? Calculate how many LED strips you need to use? Available colors? specific size requirements.

● Design drawings and quotation:

The team of engineers will issue simple design drawings as required and make quotations based on the data. We will revise and re-quote if there is a need to change.

● Make proto type and testing:

After the quotation is accepted, the factory will make proto type, after the test is completed. Send the video and test data to you for reference. The samples will be sent out when the data is acceptable.

● After the sample test is OK mass production.

After the sample test is OK, we will make small batch production. These small batches of products will be tested again in the actual use environment. If any defects are found, improvement measures are taken to perfect the product.

If you have a correct understanding of the various parameters of the led strip, you will not be too entangled in a certain parameter. To achieve the effect you want, there are actually many different methods, and many methods can be tried. In-depth communication of product requirements with an experienced LED strip manufacturer can save time and effort and bring the best product solutions.